Yoking the Future: Yoke Type Track Rollers in Advanced Robotic Applications

In today's rapidly evolving world of robotics, where automation and precision play a crucial role in industries such as manufacturing, logistics, and healthcare, the demand for high-quality components is on the rise. One such component that has gained significant popularity in recent years is the yoke type track rollers, manufactured by THB BEARINGS.

THB BEARINGS, a renowned brand in the field of bearings, has been at the forefront of developing innovative solutions to meet the ever-increasing demands of the robotics industry. Their yoke type track rollers have emerged as a game-changer, offering exceptional performance and durability in advanced robotic applications.

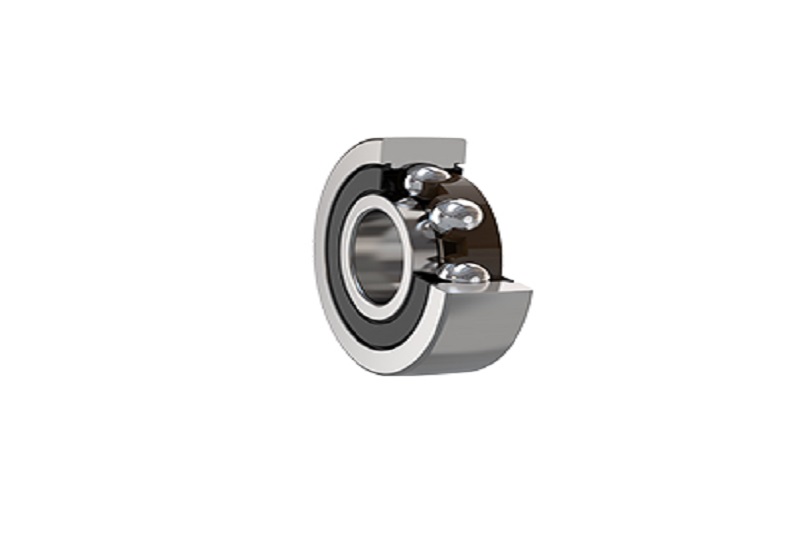

What are yoke type track rollers, and why are they important in the robotics industry? Yoke type track bearing rollers are specialized bearings designed to provide support and guidance to track systems used in various robotic applications. These rollers are equipped with an outer ring, a rolling element, cage assembly, and sealing arrangements, all meticulously engineered to withstand heavy loads, high speeds, and harsh operating conditions.

Enhanced Performance and Versatility

Yoke type track rollers are known for their superior performance and versatility, making them an ideal choice for a wide range of robotic applications. Whether it's guiding linear motion in robotic arms, conveyor belts, or transportation systems, these rollers ensure smooth and precise movement, enabling robots to perform intricate tasks with accuracy and efficiency.

Durability and Reliability

The demanding nature of robotic applications places immense stress on components, requiring them to endure extreme conditions while maintaining optimal performance. Yoke type track rollers from THB BEARINGS are manufactured using high-quality materials and advanced technologies, ensuring exceptional durability and reliability. These rollers are designed to withstand heavy loads, shock, and vibration, making them an ideal solution for robotic applications in challenging environments.

Easy Installation and Maintenance

Another advantage of yoke type track rollers is their ease of installation and maintenance. With a simple design and standardized dimensions, these rollers can be easily mounted and integrated into existing robotic systems, reducing downtime and streamlining operations. Additionally, their robust construction minimizes the need for frequent maintenance, ensuring uninterrupted performance and cost-effectiveness for robotics applications.

Future Outlook and Innovations

As the robotics industry continues to advance, the demand for yoke type track rollers is expected to grow exponentially. Manufacturers like THB BEARINGS are continuously investing in research and development to enhance the performance of these rollers and cater to emerging robotic applications. With futuristic concepts like collaborative robots (cobots) and autonomous vehicles gaining traction, yoke type track rollers will play a vital role in enabling smoother and more efficient robotic operations.

In conclusion, yoke type track rollers have become an essential component in advanced robotic applications. With their enhanced performance, durability, and easy installation, these rollers are revolutionizing the way robots operate in industries across the globe. As robotics technology continues to evolve, manufacturers like THB BEARINGS are poised to lead the way with innovative solutions, ensuring a brighter future for the robotics industry.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano