Analysis of the Application of Turntable Bearings in Various Fields

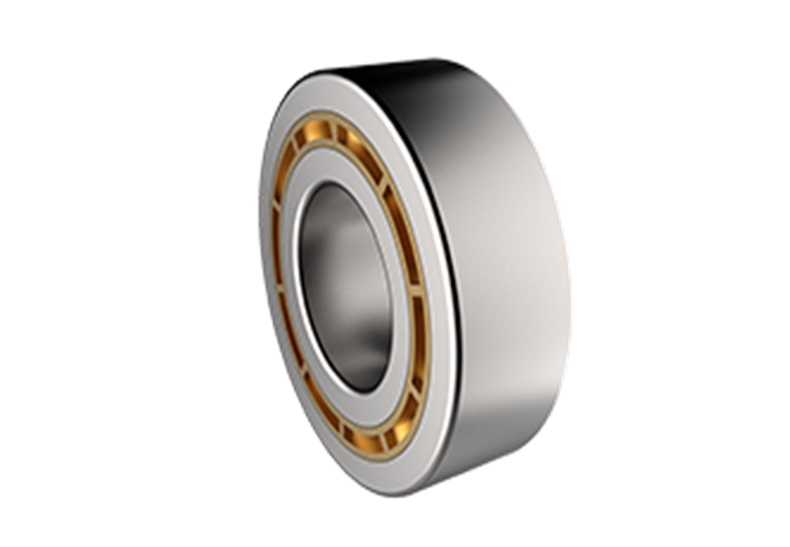

Turntable bearings, also known as rotating support, are large bearings that can simultaneously withstand large axial loads, radial loads, and moments. Turntable bearings generally have mounting holes, internal or external gears, lubrication oil holes, and sealing devices. The main structure is compact, the guidance is reliable, and maintenance is convenient.

Turntable bearings have various structural types, including toothless, external-toothed, and internal-toothed four-point contact ball bearings, double-row angular contact ball bearings, crossed cylindrical roller bearings, crossed tapered roller bearings, and three-row cylindrical roller combination bearings. Among them, four-point contact ball bearings have higher static load capacity, crossed cylindrical roller bearings have higher dynamic load capacity, and crossed tapered roller bearings can achieve greater support rigidity and higher rotational accuracy through preloading. Turntable bearings are widely used in large rotating equipment such as cranes, excavators, construction machinery, port machinery, ship machinery, high-precision radar machinery, and missile launchers.

Application of turntable bearings in wind turbines

The yaw bearing is installed at the connection between the tower and the nacelle, and the pitch bearing is installed at the root of each blade and the connection of the hub. Each wind turbine uses one set of yaw bearings and three sets of pitch bearings. The material of the yaw and pitch bearing raceway is 42CrMo, and the heat treatment adopts integral quenching and tempering, with the roller surface being quenched. The yaw and pitch bearings have complex loads and are subjected to large impacts and vibrations. Therefore, the bearings must withstand large loads when subjected to impacts. The service life of wind turbines requires 20 years, and the installation cost of bearings is high. Therefore, the service life of yaw and pitch bearings must also reach 20 years. The matrix hardness of the bearing raceway is 240-280HB, which can withstand impact without plastic deformation. At the same time, the surface hardness of the roller after quenching reaches 55-62HRC, which can increase the contact fatigue life and ensure the long service life of the bearing.

Application of turntable bearings in ship cranes

Ship cranes generally use turntable bearings with a structure of double-row different-diameter balls, four-point contact balls, and three-row ball internal tooth. According to the different carrying capacities, three-row ball turntable bearings are usually used for heavy-duty cranes, and four-point contact ball turntable bearings and double-row different-diameter ball turntable bearings are used for light-duty cranes. The cranes work in an environment of -20℃-+45℃, and this type of bearing has high requirements for the mechanical properties of the material.

Application of turntable bearings in offshore platform cranes

According to the carrying capacity requirements, offshore platform cranes usually use four-point contact ball turntable bearings and three-row roller internal tooth turntable bearings. Turntable bearings used in offshore platform cranes have special material requirements, and the mechanical properties of the material must ensure the safety factor under the ultimate load. The finished bearings must be certified by the classification society.

Application of turntable bearings in mobile port cranes

Mobile port cranes generally use three-row cylindrical roller industrial turntable bearings with an inner or outer diameter of 4 meters, which can withstand high overturning moments.

Application of turntable bearings in stacker reclaimers

The turntable bearings used in stackers usually adopt ball-column joint type, three-row roller type, and cross roller type, most of which have a diameter of more than 3 meters. Due to the poor working environment and large amount of dust, these bearings have the characteristics of high load capacity, long service life, and good sealing performance.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano