Silent Efficiency: Bearing Noise Analysis in Precision Machinery

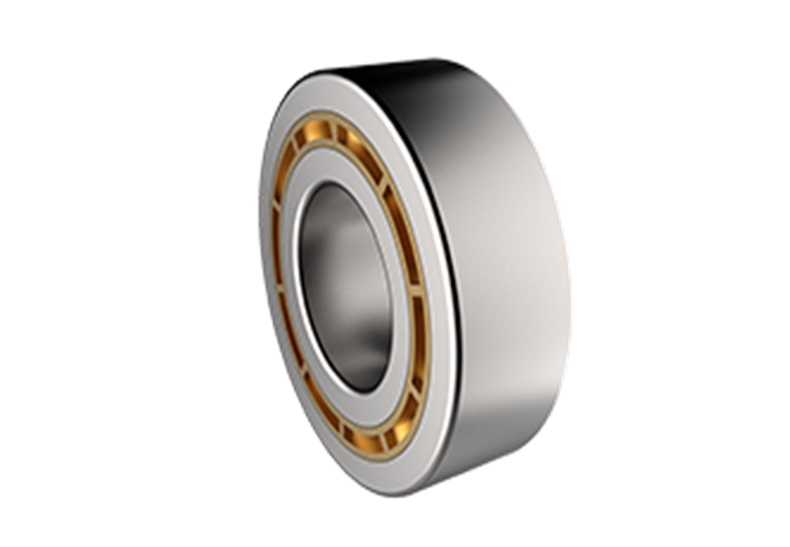

In the world of precision machinery, where smooth and accurate performance is paramount, bearing noise analysis plays a crucial role. Bearings are essential components in many machines, enabling smooth rotation and movement. However, any abnormal noise stemming from bearings can indicate significant issues that can impact the efficiency and reliability of the machinery. Therefore, it is imperative to understand the importance of bearing noise analysis and how it contributes to silent efficiency in precision machinery.

The Essence of Precision Machinery

Precision machinery is designed to perform with exceptional accuracy and reliability. It finds application in various industries, including automotive, aerospace, medical devices, and manufacturing. These machines rely on bearings to support rotating shafts and ensure smooth movement while minimizing energy loss and friction. Any deviation from optimal performance can lead to failures, downtime, and increased maintenance costs. Hence, the analysis of bearing noise becomes critical to identify and resolve potential issues proactively.

The Impact of Bearing Noise in Machinery

Bearing noise acts as an indicator of potential problems within the machinery. Vibrations and abnormal sounds emitted by bearings signify poor lubrication, misalignment, fatigue, or even impending failure. These issues can negatively impact the machine's efficiency, reduce performance, and shorten the bearing's lifespan. By conducting regular bearing noise analysis, engineers can detect and address problems at an early stage, preventing costly breakdowns and extending the life of the machinery.

Methodology of Bearing Noise Analysis

Bearing noise analysis involves a systematic approach to identify, measure, and diagnose noise sources within machinery. This process includes using specialized equipment, such as vibration sensors and spectrum analyzers, to detect and analyze the frequency and amplitude of bearing noise. Additionally, visual inspections and computer-aided software can aid in identifying potential faults within the bearings. By studying the collected data and comparing it to the expected noise profile, experts can determine the root cause of the noise and develop appropriate solutions.

Benefits of Bearing Noise Analysis

Regular analysis of bearing noise offers several benefits in precision machinery:

Increased Efficiency: Identifying and resolving noise-related issues leads to improved machine performance, ensuring smoother operations and higher productivity.

Reduced Maintenance Costs: Timely detection of bearing faults allows for proactive maintenance, preventing the development of more severe problems. This helps in minimizing repair costs and avoiding unexpected breakdowns.

Extended Lifespan: By resolving bearing noise issues promptly, the overall life expectancy of the machinery can be significantly prolonged, leading to higher return on investment.

Enhanced Safety: Abnormal bearing noise can be an early warning sign of potential failures. Addressing these issues promptly reduces the risk of accidents, ensuring a safer working environment for operators.

Silent efficiency is of utmost importance in precision machinery, and bearing noise analysis plays a vital role in achieving this objective. By conducting regular analysis, potential problems can be detected early, leading to increased efficiency, reduced maintenance costs, extended machinery lifespan, and enhanced safety. It is crucial for manufacturers and operators to recognize the significance of bearing noise analysis and incorporate it into their maintenance strategies to ensure optimal performance and reliability of precision machinery. From automotive production lines to aerospace control systems, bearing noise analysis is the key to maintaining silent efficiency.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano