Self-Aligning Linear Ball Bearings in Industrial Automation

Self-aligning linear ball bearings are a key component in industrial automation machinery, providing smooth movement and precise positioning in various applications. These bearings are designed to accommodate misalignment and reduce friction, ensuring efficient operation and prolonging the lifespan of equipment.

In today's competitive manufacturing environment, companies strive to increase productivity and minimize downtime. Self-aligning linear ball bearings play a crucial role in achieving these goals by providing reliable motion control solutions in automated systems. These bearings offer high load-carrying capacity and accurate linear motion, making them ideal for demanding industrial applications.

What are self-aligning linear ball bearings?

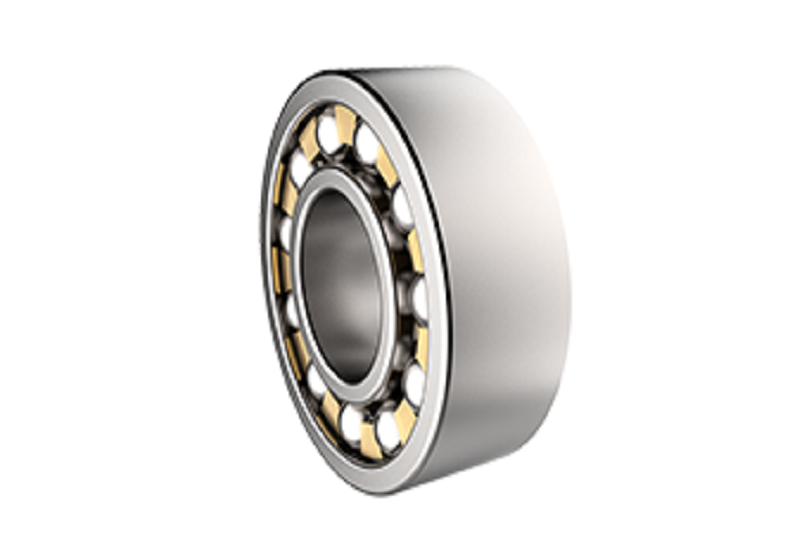

Self-aligning linear ball bearings are a type of linear motion bearing that consists of an outer raceway, a ball cage, and a series of steel balls. The design allows the bearing to compensate for angular misalignment between the shaft and housing, providing smooth and precise linear motion. These bearings are commonly used in automation equipment, such as robotic arms, pick-and-place systems, and conveyor systems.

Benefits of using self-aligning linear ball bearings

One of the main advantages of self-aligning linear ball bearings is their ability to accommodate misalignment, reducing the risk of premature wear and failure. This feature is particularly important in industrial automation applications where precise positioning is critical. Additionally, these bearings offer low friction and high efficiency, resulting in smooth and accurate motion control. The high load-carrying capacity of self-aligning linear ball bearings allows them to support heavy loads and withstand demanding operating conditions.

Applications of self-aligning linear ball bearings in industrial automation

Self-aligning linear ball bearings are widely used in industrial automation machinery for a variety of applications. In robotic arms, these bearings help to provide smooth and precise motion for picking and placing objects. In conveyor systems, self-aligning linear ball bearings ensure reliable operation and efficient material handling. These bearings are also used in CNC machines, packaging equipment, and linear actuators, where accurate linear motion is essential for optimal performance.

Maintenance and replacement of self-aligning linear ball bearings

To ensure the proper functioning of industrial automation equipment, it is important to perform regular maintenance on self-aligning linear ball bearings. This includes cleaning the bearings, inspecting for wear or damage, and lubricating as needed. In the event of bearing failure, it is crucial to replace them promptly to prevent further damage to the equipment. When selecting replacement bearings, it is essential to choose high-quality self-aligning linear ball bearings that are compatible with the application and operating conditions.

In conclusion, self-aligning linear ball bearings are essential components in industrial automation machinery, providing reliable motion control solutions for a wide range of applications. These bearings offer numerous benefits, including the ability to accommodate misalignment, reduce friction, and support heavy loads. By incorporating self-aligning linear ball bearings into automated systems and performing regular maintenance, companies can improve productivity, minimize downtime, and extend the lifespan of their equipment.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano