Practical Skills for Fault Diagnosis of Rolling Bearings

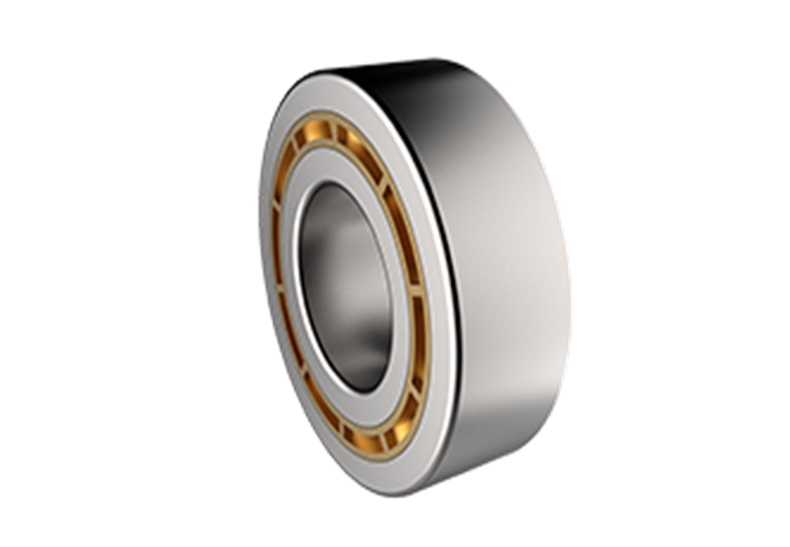

Rolling bearings are widely used in equipment. The status of rolling bearings is directly related to the operating status of rotating equipment. Especially in continuous large-scale production enterprises, it is widely used in important parts of large rotating equipment. Therefore, in actual production, do a good job of rolling bearing status monitoring and Fault diagnosis is an important part of equipment maintenance and management. After long-term practice and exploration, the manufacturer has accumulated some practical skills for actual fault diagnosis of rolling bearings.

Now, let THB Bearings, one of the most professional China rolling bearing manufacturers and an experienced supplier of bearing application solutions, tell you practical skills for fault diagnosis of rolling bearings.

1. Abnormal operation characteristics and diagnostic skills of rolling bearings

Nowadays, counterfeit and shoddy bearings will inevitably enter enterprises and equipment, and serious failures caused by these flow bearings are often sudden and catastrophic. Such as the sudden fracture of the bearing cage, the sudden fracture of the inner and outer rings of the bearing, etc., these faults will cause the rotor to lock the shaft, and in severe cases, the rotor or equipment will be scrapped. In actual monitoring and diagnosis, it is necessary to diagnose the condition of rolling bearings as soon as possible, and replace fake and inferior bearings in time to avoid major accidents. In a large number of such accidents, some practical skills have also been accumulated, that is, to monitor the vibration state of such bearings at the initial stage of operation after installation, and to perform frequency spectrum analysis. It is found that the frequency spectrum of the bearing has its unique characteristics in the early stage of operation, that is, the power frequency of the equipment generally does not account for the main component. However, the total value of vibration is not large, and the vibration standard is used to judge that the vibration is qualified. At this time, it is necessary to be vigilant. This state is manifested by defects in bearing components, etc., and its failure is often very fast and very sudden. When diagnosing the faults of these counterfeit and shoddy bearings, it is necessary to pay more attention to the frequency spectrum and vibration time domain of the normal operation of high-quality bearings on the equipment, so that the bearing fault can be judged in time when such abnormal frequency spectrum occurs, and equipment accidents can be avoided.

2. Practical rapid diagnosis skills for rolling bearings

In actual condition monitoring, it is often only necessary to judge whether the rolling bearing product is good or bad, and how long it can last, but it is often not practical to diagnose a fault in a certain part of the bearing in precision analysis and diagnosis. Due to the influence of factors such as working conditions in practical precision diagnosis, it is often impossible to find out the characteristic frequency corresponding to the rolling bearing. Although the wavelet analysis and fast resonance demodulation analysis technologies developed in recent years are relatively accurate, they require a large investment in equipment and more analysis, and are generally seldom used by on-site fault diagnosis personnel. In the practical diagnosis, the combined judgment of dimensioned parameters and dimensionless parameters is adopted to carry out rapid fault diagnosis of bearings, that is, frequency vibration velocity in frequency spectrum analysis is used in combination with bearing kurtosis value for comprehensive diagnosis. When both conditions exceed the standard, it is judged that there is a fault in the bearing.

After years of practice, this judgment method has proved to be very practical for the fault diagnosis of rolling bearings. The judgment is fast and accurate, and the accuracy rate exceeds 90%. The diagnosed bearings are basically in the late stage of failure, which has very good economic benefits. In addition, when the low-frequency vibration of the rolling bearing is very large, after excluding structural factors such as unit misalignment, unbalance, loose structure, and foundation resonance, even if there is no characteristic frequency of the rolling bearing, it should be decisively judged that the rolling bearing is faulty and repaired.

3. Practical rolling bearing frequency spectrum analysis and diagnosis skills

Now the use of data collectors is more common. But pay attention to the following tips in practice. For the vibration signal with small vibration, low bearing kurtosis and complex spectrum, when it is difficult to judge whether there is a fault on site, the vibration signal is collected and sent to the computer for precise analysis. At this time, perform routine analysis first to check whether the vibration velocity spectrum and bearing kurtosis are close to the standard, and then use the power spectrum to check whether the vibration energy exceeds the standard. If the power spectrum is not large, observe various frequency components in the spectrum. If the spectral line corresponds to an integral multiple of the power frequency, you should focus on finding faults in the unit structure; if it is a fractional multiple of the power frequency, and there are many decimal places, you should focus on finding the frequency of the rolling bearing. If there is, there is a fault in the bearing , if not, after troubleshooting other component failures, vigilance should be aroused and monitoring should be strengthened. It is actually found that many vibrations do not exceed the standard, but bearing failures occur. Once the characteristic frequency of the bearing appears or is close to the characteristic frequency spectrum of the bearing, it should be judged that there is a fault in the bearing, and then according to the magnitude, trend analysis or maintenance can be arranged.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano