The Function of V Groove Bearing Track in Automated Warehousing

In the fast-paced world of automated warehousing, every component of the system plays a crucial role in ensuring smooth operations and optimal efficiency. One such component that is often overlooked but is essential for the proper functioning of conveyor systems is the V groove bearing track. This blog will delve into the significance of V groove bearing track in automated warehouses and how it contributes to the overall productivity of the system.

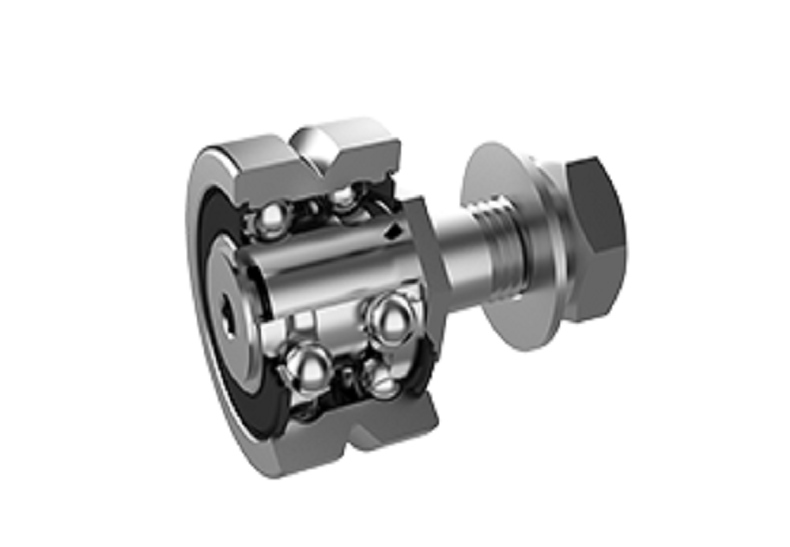

Understanding V Groove Bearing Track

V groove bearing tracks are specialized tracks that are designed to guide and support the movement of various materials and products in automated conveyor systems. These tracks feature a V-shaped groove that allows for precise alignment and smooth movement of the rollers or bearings that run along them. This design ensures that the materials can move along the track with minimal friction and resistance, leading to more efficient and reliable handling of goods in the warehouse.

Increased Stability and Precision

One of the key functions of V groove bearing tracks is to provide stability and precision to the conveyor system. The V-shaped groove in the track ensures that the rollers or bearings have a secure and accurate path to follow, reducing the chances of misalignment or slippage. This stability and precision are critical in automated warehouses where precise movement and alignment of goods are essential for the success of the operation.

Reduced Wear and Tear

Another important function of V groove bearing tracks is to reduce the wear and tear on the conveyor system. The smooth and uniform surface of the track ensures that the rollers or bearings experience minimal friction as they move along the track, leading to less wear and tear on the components. This not only extends the lifespan of the conveyor system but also reduces maintenance costs and downtime, contributing to a more efficient and cost-effective operation.

Optimal Performance

Overall, the function of V groove bearing tracks in automated warehousing is to ensure optimal performance of the conveyor system. By providing stability, precision, and reduced wear and tear, these tracks play a crucial role in maintaining the efficiency and productivity of the warehouse. With V groove bearing tracks in place, materials can be moved swiftly and smoothly along the conveyor system, leading to faster processing times and increased throughput.

In conclusion, V groove bearing tracks are an essential component of automated warehousing systems, providing stability, precision, and reduced wear and tear to the conveyor system. By ensuring smooth movement of materials and products, these tracks contribute to the overall productivity and efficiency of the warehouse. To maximize the performance of your automated warehouse, it is crucial to invest in high-quality V groove bearing tracks that are designed to withstand the rigors of continuous use and provide reliable support for your conveyor system.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano