From Factory Floors to Warehouses: Self-Aligning Linear Ball Bearings in Manufacturing

Introduction to THB BEARINGS

Welcome to the world of THB BEARINGS, a leading manufacturer of high-quality self aligning linear ball bearings. With a strong presence in the manufacturing industry, THB BEARINGS is revolutionizing the way various sectors manage their operations, enhancing efficiency and productivity. In this blog post, we will delve into the innovative technology of self aligning linear ball bearings and their crucial role in the manufacturing process.

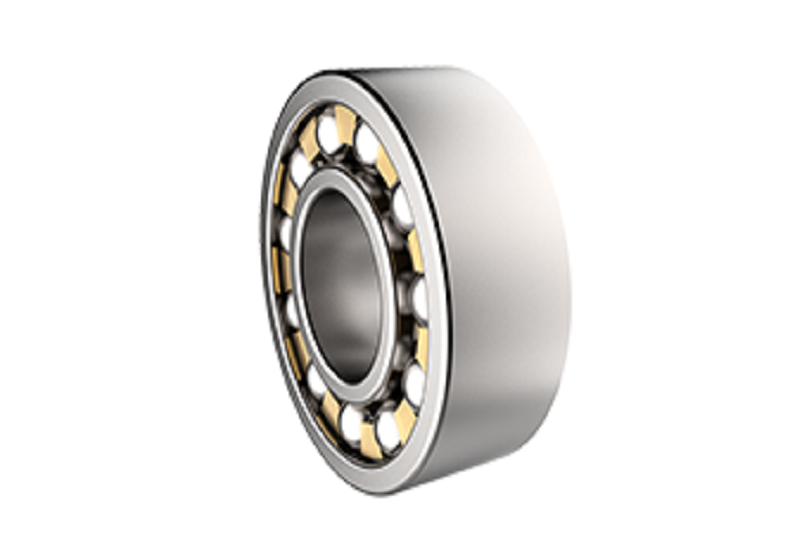

Understanding Self Aligning Linear Ball Bearings

Self-aligning linear ball bearings are an essential component in modern manufacturing systems. These bearings are designed to support linear motion with a high degree of precision, while also effectively compensating for misalignment. When installed correctly, self aligning linear ball bearings ensure smooth and reliable movement on both factory floors and within warehouse environments.

The innovative design of self aligning linear ball bearings enables them to accommodate misalignment caused by inaccurate mounting or shaft deflection. As a result, they improve operational performance, minimize downtime, and increase the longevity of machinery used in manufacturing processes.

Enhancing Efficiency and Performance in Manufacturing

By implementing self aligning linear ball bearings in their systems, manufacturing facilities experience a range of benefits. Let's explore how these bearings contribute to improved efficiency and performance:

Fault Tolerance: With self aligning linear ball bearings, manufacturing equipment can tolerate slight misalignments. This reduces equipment wear and tear, overall maintenance costs, and the risk of unexpected breakdowns.

Smooth Operation: Linear movements become effortless and consistent, leading to smoother material handling on factory floors and streamlined processes across different stages of production. This ultimately boosts productivity and reduces the risk of product defects.

Increased Lifespan: By reducing stress on machinery and minimizing the effects of misalignment, self aligning linear ball bearings contribute to extended equipment lifespan. This translates into significant cost savings for manufacturing facilities in the long run.

Applications in Manufacturing

The versatility of self aligning linear ball bearings makes them suitable for a range of manufacturing applications. Here are a few notable examples:

Conveyor Systems: Self aligning linear ball bearings ensure smooth and accurate movement of materials along conveyor belts, enhancing the flow of goods in manufacturing and warehouse operations.

Robotic Arms and Automated Production Lines: Precision is of utmost importance when it comes to robotic arms and automated production lines. Self aligning linear ball bearings enable accurate positioning, allowing for precise assembly and quality control processes.

Packaging Machinery: The packaging industry relies on efficient and consistent movement of products during the packaging process. Self aligning linear ball bearings contribute to seamless and reliable motion of packaging machinery, ensuring optimal productivity and product integrity.

In conclusion, self aligning linear ball bearings play an integral role in modern manufacturing, revolutionizing the way industries operate. By enhancing efficiency, minimizing downtime, and increasing equipment lifespan, THB BEARINGS' self aligning linear ball bearings are a game-changer for manufacturers worldwide, enabling them to meet consumer demands with precision and excellence.

So, if you're looking to optimize your manufacturing processes or enhance the performance of your machinery, consider investing in self aligning linear ball bearings from THB BEARINGS. Experience the transformative power of this cutting-edge technology and stay ahead in the ever-evolving manufacturing landscape.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano