The Function of Cam Yoke Roller Bearing in Port Facilities

In the bustling world of port facilities, where efficiency and reliability are paramount, precision components like the cam yoke roller bearing play an essential role. This blog dives into the unique features and functions of the cam yoke roller bearing, exploring its applications and the transformative impact it has on the operations within port facilities.

Understanding the Cam Yoke Roller Bearing Design

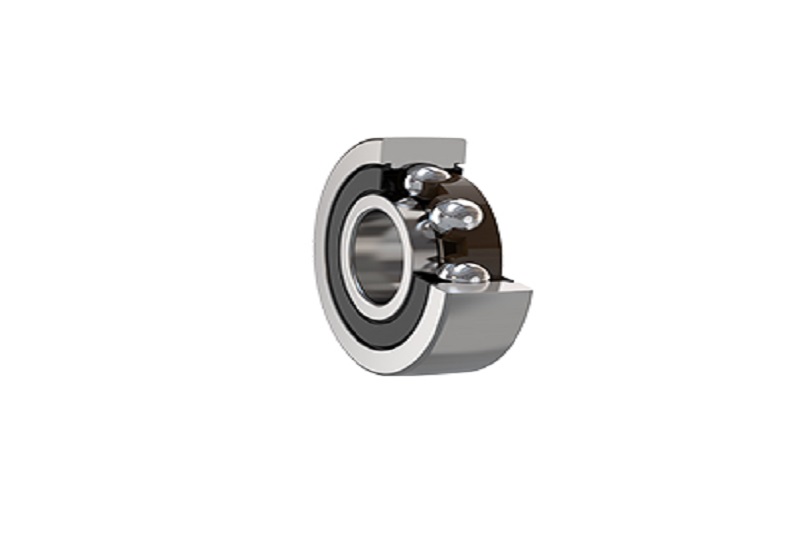

Before delving into its application, it's crucial to understand the design of the cam yoke roller bearing. This specialized bearing features a cylindrical outer race, a crowned or flat yoke stud for mounting, and a full complement of needle rollers. The yoke stud allows for easy installation and positioning, while the needle rollers ensure efficient load distribution. This design makes cam yoke roller bearings ideal for applications demanding both radial and axial load support.

Applications in Port Facilities

Cam yoke roller bearings find a critical role in various applications within port facilities, contributing to the seamless functioning of crucial equipment. In conveyor systems for loading and unloading cargo, these bearings are often employed to support idler rollers. Their ability to handle high loads and provide reliable performance ensures the smooth and continuous movement of conveyor systems, enhancing the overall efficiency of cargo handling operations.

Enhancing Track Systems for Container Handling

In the intricate world of container handling, where precision is essential, cam yoke roller bearings are deployed in track systems. These bearings facilitate the smooth movement of cranes and other handling equipment along tracks, ensuring precise positioning and reducing wear on the equipment. The crowned yoke stud design of these bearings aids in maintaining alignment, contributing to the overall stability and reliability of track systems in port facilities.

Minimizing Downtime and Maintenance Costs

One of the key advantages of using cam yoke roller bearings in port facilities is their contribution to minimizing downtime and maintenance costs. The robust design and efficient load-carrying capacity of these bearings result in reduced wear and extended service life. This reliability is crucial in port operations, where any downtime can have significant implications on the overall efficiency of cargo handling processes.

Future Developments and Advancements

As technology in port facilities evolves, so do the requirements for precision components like cam yoke roller bearings. Ongoing developments in materials, lubrication, and design contribute to enhanced performance and longevity. Innovations such as advanced coatings and seals further position cam yoke roller bearings as critical components, driving the evolution of port facility equipment.

In conclusion, the application of cam yoke roller bearings in port facilities underscores their indispensable role in ensuring the efficiency and reliability of crucial equipment. From conveyor systems to track systems for container handling, these bearings contribute to the seamless movement and precise positioning of equipment. As port facilities continue to embrace technological advancements, cam yoke roller bearings will remain at the forefront, steering the course toward enhanced performance, reduced downtime, and optimal efficiency in cargo handling operations.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano