【Industrial Fan Bearing Recommendations】Bearing application of jet fan

When passing through the long tunnel, there are many fans hanging at the top of the tunnel, those are tunnel fans which is also called jet fan.

Fans in the tunnel

What is a jet fan?

The jet fan is a special type of axial flow fan, which makes large-scale and long-distance air transfer into high-speed linear air transfer.

Close view of operating jet fan

There are mute pipes on both sides of the jet fan, which can effectively lower the noise of operating fan. A suitable high-quality bearing can further lower the noise in the channel and ensure the long-term reliable operation of the equipment.

1D mute channel jet fan

2D mute channel jet fan

Jet fan bearing installation for special scenarios

Usually, the bearing applications of the jet fan are installed inside the drive motor. However, in some special scenarios, it is required to have more stable support for longer shafting. At this time, professional bearing installation and selection are particularly important. For this design, one end is the spindle impeller, the other end is connected with the coupling and motor. Usually use bearing auxiliary support spindle, which can make the spindle uniform and stable operation. For example, the special jet fan shown below provides more wind direction and is easy to disassemble, reducing the time for disassembly and maintenance when the jet fails, and providing wind direction guidance in the tunnel more quickly.

Directable jet fan

Bearings in a jet fan drive motor

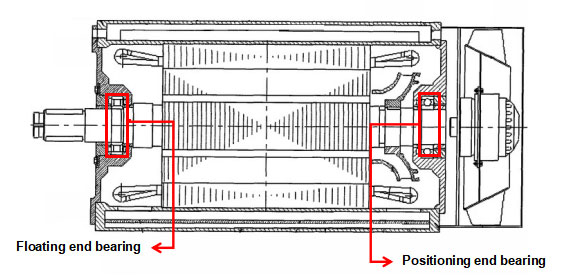

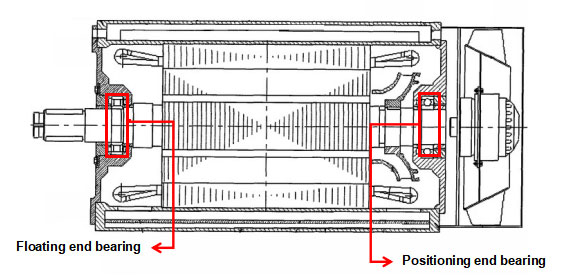

When the fan is running, the high-speed flowing wind makes the bearing bear the axial load. The design of long ventilation duct has high requirements for the centering performance of the bearing at both ends of the long shaft. Considering the fan working under the high-speed, the shaft will heat up and lead to axial extension, the bearing support needs to have a certain floating performance.

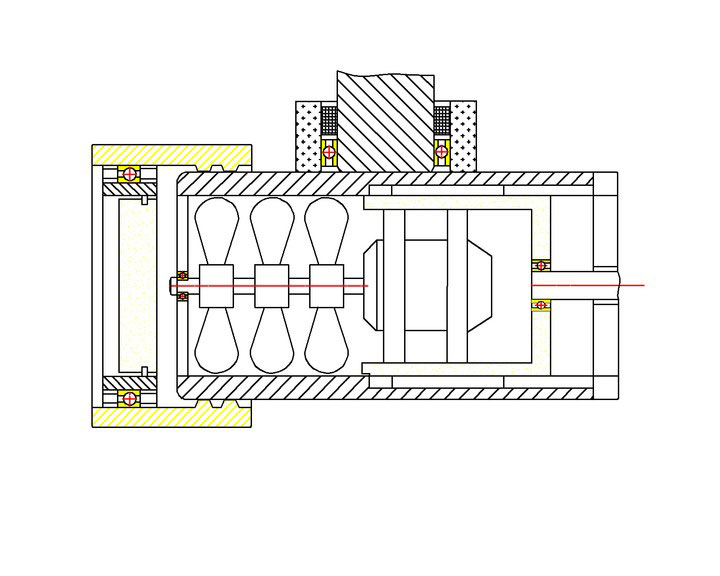

The fan drives motor spindle and bearing, at both ends of the shaft are equipped with positioning end bearing and floating end bearing. The cantilever load of the motor makes it necessary to configure bearings that bear radial load and axial load respectively when it works. Generally, cylindrical roller bearings (bearing radial load) are used at the floating end, deep groove ball bearings or angular contact ball bearings (bearing axial and auxiliary radial loads) are used at the positioning end, and spherical roller bearings are used for the spindle of heavy fan.

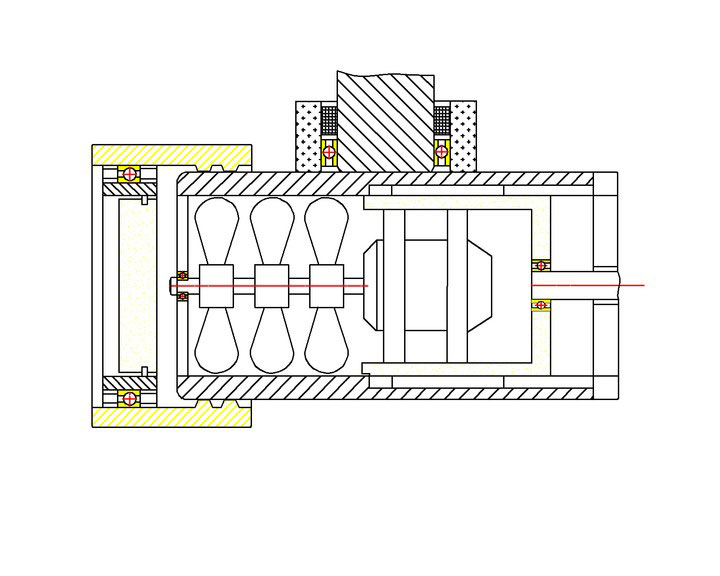

Drive motor drawing

·Deep groove ball bearing

The radial bearing capacity of deep groove ball bearing is lower, which can load a certain axial load and obtain higher ultimate speed. It is standardized and cost-effective, which is a common choice.

Deep groove ball bearing

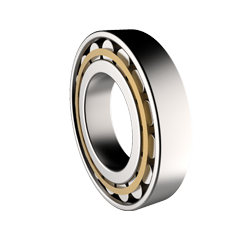

·Angular contact ball bearings

There is a certain angle between the force transmission direction of angular contact ball bearing and the vertical line of rotation axis. While bearing radial force, it can bear large axial load according to the size of the contact angle, and the rated speed is also significantly improved. It can be accurately positioned and stably supported, which is selected according to the corresponding working conditions.

Angular contact ball bearings

·Taper roller bearings

In the application of positioning bearings, tapered rollers are less adaptable than spherical roller bearing at long axes, but special working conditions, such as greater axial load and higher positioning accuracy requirements, also have unique adaptability.

Tapered roller bearing

·Cylindrical roller bearing

The centripetal cylindrical roller bearing ( NU & N type ) as floating end bearing, because this type of bearing has high radial bearing capacity, limit speed and precision also have good performance. As a floating end bearing can be a good support for radial load stability, with a longer service life, reduce maintenance costs.

Cylindrical roller bearing

·Spherical roller bearing

Self-aligning roller bearing has high radial bearing capacity, and can cope with high axial load. It has a very good adaptability to the long axis alignment of the fan, and can work stably on the shaft with severe vibration of the fan. Almost all working conditions can be very well adapted, ensure the overall stability and life of the equipment.

Spherical Roller Bearings

Spare parts of the fan

Considering the vibration during the operation of the tunnel fan, each bearing can be equipped with a bearing hou€sing to improve stability. The installation of bearing seal ring can effectively increase the service life of bearings.

As an important transmission component of tunnel fans, bearings require relevant fluid dynamics analysis and simulation design in the selection process. This can ensure the normal and stable operation of the fan under various working conditions. KIS can provide you with a full range of bearing application technology services.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano