Choose THB Bearings for Track Roller Bearings

THB Bearings is a leading track roller bearing factory and manufacturer based in China. With years of experience in the industry, THB Bearings has become a well-known track roller bearing supplier, offering high-quality bearings and customized solutions for various applications across different industries.

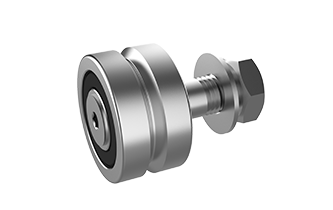

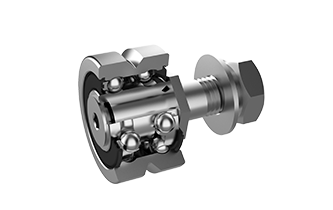

As a reliable track roller bearing manufacturer, THB Bearings has a comprehensive product range, including cam followers, stud type track rollers, and yoke type track rollers. These products are made with advanced technology and high-quality materials, ensuring superior performance and durability.

THB Bearings takes pride in its ability to provide customized solutions for its clients, regardless of their industry or application. The company's team of experts works closely with customers to understand their needs and provide tailor-made solutions to meet their requirements.

Whether you need track rollers for heavy-duty machinery or precision equipment, THB Bearings is your go-to track roller bearing supplier. With a commitment to quality and customer satisfaction, THB Bearings has earned a reputation as a trusted track roller manufacturer in the industry.

Application of Track Bearing Roller

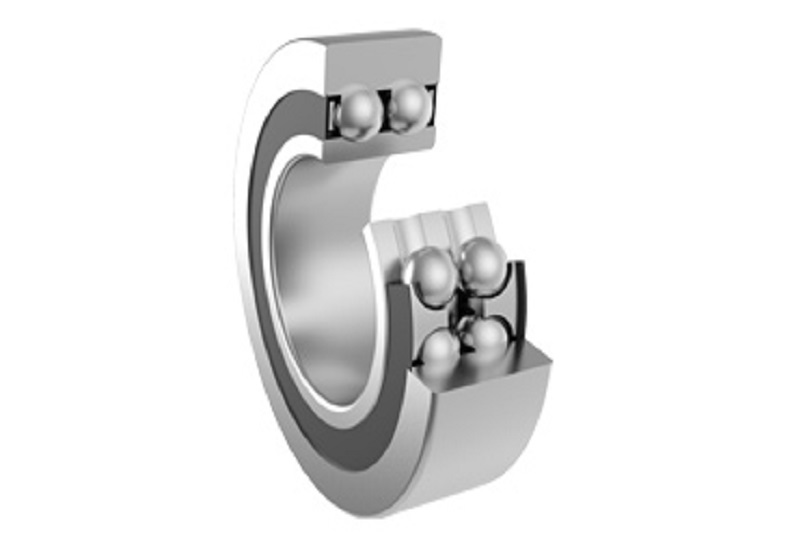

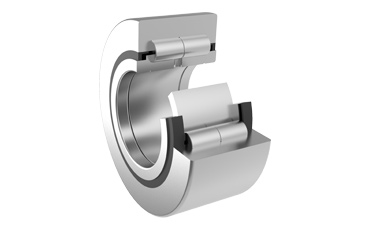

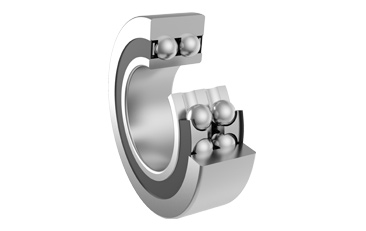

Track roller bearings are a type of rolling element bearing designed to support and guide heavy loads in applications that involve rolling or sliding motion, such as conveyor systems, material handling equipment, and industrial machinery. They consist of an outer ring, a series of rollers, and an inner ring. The rollers are held in place by a cage, which maintains their position relative to each other and to the outer and inner rings.

Track roller bearings are commonly used in track rollers or cam followers, which are widely used in industrial applications such as construction equipment, material handling, packaging machinery, and agricultural equipment. They are also used in a variety of other applications that require high load capacity, high durability, and precision guidance of rolling elements, such as machine tools, printing presses, and robotics.

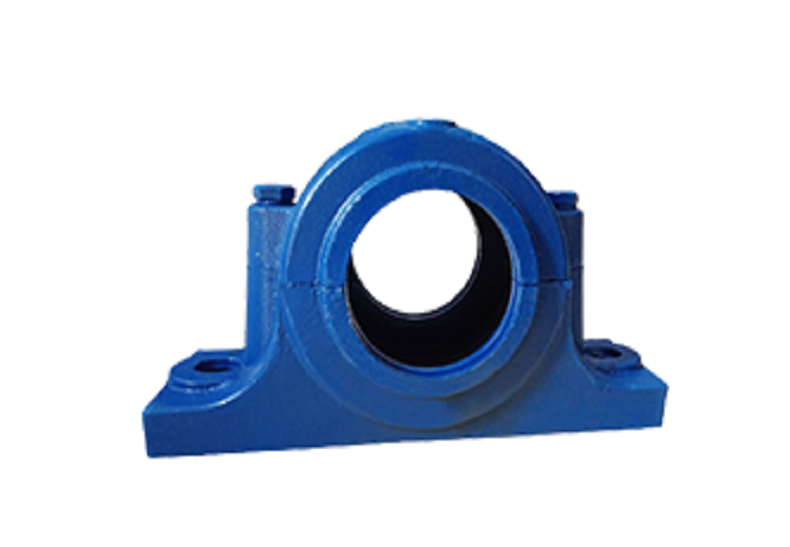

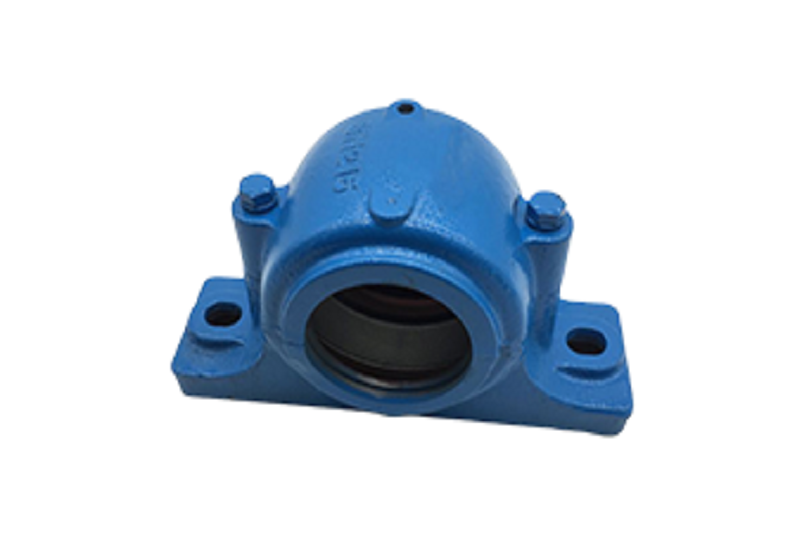

Track roller bearings are designed to operate in harsh environments, including high temperatures, high humidity, and dirty or dusty conditions. They are available in a range of sizes and configurations, including stud-type and yoke-type rollers, and can be customized to meet specific application requirements.

If you are looking for a reliable track roller manufacturer, look no further than THB Bearings. Contact us now for track roller bearing catalogue and track roller bearing solutions for your specific applications.

| Automotive assembly | Cement and concrete plant application rollers | Glass fiber manufacturing | Food and beverage production | Foundries and mills |

| Medicines | Metalworking | Mining | Pharmaceutical industry | Pulp and paper |

| Sand and gravels | Scientific research | Shipbuilding | Wood products |

|

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano