How to Scientifically Choose Tapered Roller Bearings!

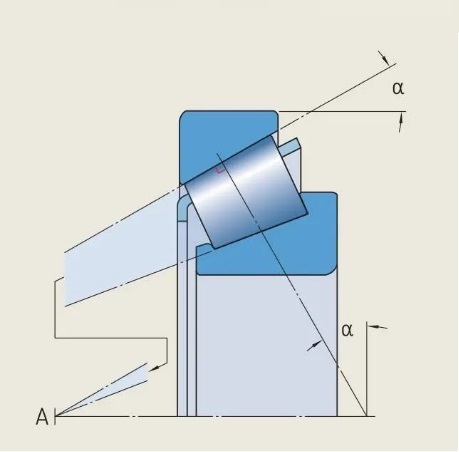

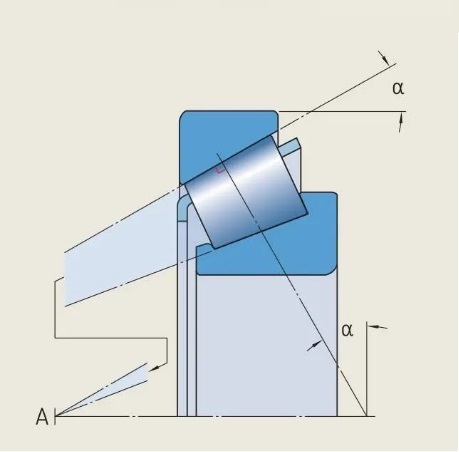

Tapered Roller Bearings feature conical inner and outer ring raceways and conical rollers. This design allows them to withstand combined loads, namely radial and axial loads acting simultaneously. The extensions of the raceways converge at a single point on the bearing axis (ApexA), to achieve true rolling motion, thereby resulting in low frictional torque during operation. Tapered Roller Bearings's axial load carrying capacity increases with the contact angle a. The contact angle typically ranges between 10° to 30° , and relates to the computation coefficient e. The larger the value of e, the greater the contact angle.

Characteristics of Tapered Roller Bearings

Low Friction

The end face of the rollers and the ribs have been optimized, and the guiding surface of the ribs has been polished to promote the formation of a lubricating oil film, thereby reducing friction. This also reduces frictional heat and rib wear. In addition, the bearing can better maintain preload and reduce noise levels during operation.

Long Service Life

The rollers in the bearing design have a certain crowning, Tapered Roller Bearings' roller profiles are logarithmic curve shaped. Compared to conventional straight profile rollers, the bearing can optimize the load distribution along the contact surface on the raceways, avoid stress concentration at the roller ends, and reduce sensitivity to misalignment and shaft deflection.

Enhanced Operational Reliability

The geometry of the contact surfaces of the rollers and raceways has been optimized and polished to facilitate the formation of a hydrodynamic lubricating oil film.

Consistency of Roller Profiles and Dimensions

THB Tapered Roller Bearings Suppliers use extremely precise dimensions and geometric tolerances in production to ensure that the rollers are almost identical. This precise tolerance control, combined with the high-precision raceway profiles, achieves optimized load distribution, lower noise and vibration levels, and more precise preload.

Rigid Bearing Applications

A single row Tapered Roller Bearing usually needs to be paired and adjusted with another Tapered Roller Bearing to achieve rigid bearing applications by applying preload.

Lower Maximum Temperature During Running-in Period

Tapered Roller Bearings typically have a running-in period during which conventional designs produce significant friction and wear. When the bearing is correctly mounted and lubricated, Tapered Roller Bearings' design can significantly reduce friction, frictional heat, and wear.

Separability and Interchangeability

Tapered Roller Bearings are designed as separable structures with complete interchangeability among parts of identical bearing sizes. For example, Single Row Tapered Roller Bearings are separable, allowing the parts with roller and cage assembly to be separated (Tapered Roller Bearings' outer ring) and installed separately. This helps make installation, disassembly, and maintenance inspections more convenient.

Tapered Roller Bearings supplier THB offers a variety of designs, series, and sizes of Tapered Roller Bearings. SKF also offers Tapered Roller Bearings for special application requirements. These include four-row Tapered Roller Bearings, wheel hub bearing units used in industrial, automotive, railway, and construction machinery applications, and custom Tapered Roller Bearings tailored to meet various application conditions as required by customers.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano