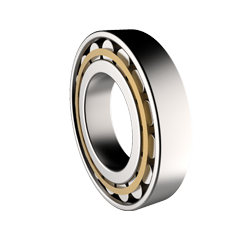

Cylindrical Roller Bearing Types

THB Bearings is a professional cylindrical roller bearing types supplier with its own cylinder roller bearing factory. We can produce different types of cylindrical roller bearings according to customers' needs. Cylindrical rollers and raceways are linear contact bearings. With huge load capacity, cylindrical roller bearing mainly bears radial load. The friction between the rolling element and the retaining edge of the ring is small, which is suitable for high-speed rotation. According to whether the ring has ribs, it can be divided into single row cylindrical roller bearings such as NU, NJ, NUP, N, NF, and double row cylindrical roller bearings such as NNU and NN. Cylindrical roller bearing has a separable structure with inner ring and outer ring.

Cylindrical roller bearings without ribs on the inner ring or outer ring, the inner ring and outer ring can move relative to the axial direction, so it can be used as a free end bearing. Cylindrical roller bearings with double ribs on one side of the inner ring and outer ring and a single rib on the other side of the ring, can bear a certain degree of axial load in one direction. Generally, stamping steel cages or solid cages made of copper alloy cars are used.

Cylindrical roller bearings are separable bearings, which are very convenient for installation and disassembly. Cylindrical roller bearings can withstand larger radial loads and are suitable for use in high-speed running situations.

This type of bearing allows a very small angular error (inclination) between the axis of the inner ring and the axis of the outer ring, only 2'~4'. Therefore, the machining accuracy of the shaft and the bearing seat is relatively high. Otherwise, uneven load or stress concentration is likely to occur in the contact part of the raceway. But after correcting the roller or raceway contact bus bar, the occurrence of stress concentration can be reduced.

Cylindrical roller bearings can be divided into single-row, double-row and multi-row cylindrical roller bearings according to the number of rows of rolling elements. Bearings of different structures are also shown in the design of the position of the ribs. Among them, the commonly used cylindrical roller bearings have the following forms.

Choose Cylinder Roller Bearings From THB Bearings

THB Bearings is a professional cylindrical roller bearing factory that specializes in providing solutions for a variety of cylindrical roller bearing applications across different industries. As a leading double row roller bearing manufacturer, THB Bearings offers a wide range of cylindrical roller bearing types to meet the specific needs of our customers.

With years of experience in the industry, THB Bearings has become a trusted cylindrical roller bearing manufacturer known for our high-quality products and exceptional customer service. We have a deep understanding of the complexities of cylindrical roller bearing applications and are able to provide customized solutions to meet the unique needs of our clients.

As a reliable cylindrical roller bearing factory, THB Bearings offers a diverse selection of products, including single and double row roller bearings, as well as customized designs to meet the needs of specific industries. Our products are widely used in applications such as automotive, aerospace, and heavy machinery, among others.

Overall, if you're looking for a trusted cylindrical roller bearing types supplier, THB Bearings is a great choice. We offer a wide range of products and can provide customized solutions to meet the specific needs of your industry.

Cylindrical Roller Bearings: Components and Uses

Cylindrical roller bearings are an essential component of many industrial applications, offering high radial load capacity and moderate thrust load capacity. These bearings are widely used in various fields, from electric motors and gearboxes to machine tools and paper machines. In this article, we will take a closer look at the components and uses of cylindrical roller bearings.

Components of Cylindrical Roller Bearings Cylindrical roller bearings are composed of several key components, including the outer raceway, inner raceway, rollers, cage, and lubrication.

The outer raceway is the outer ring of the bearing that holds and guides the rollers. It is typically made of steel and features a smooth surface to minimize friction.

The inner raceway is the inner ring of the bearing that holds and guides the rollers. Like the outer raceway, it is usually made of steel and has a smooth surface.

Rollers are cylindrical-shaped rolling elements that support the radial load of the bearing. They are typically made of high-grade steel and are precision-ground to ensure a high level of accuracy and consistency.

The cage is the component that keeps the rollers evenly spaced and separated, preventing them from rubbing against each other. It is typically made of brass, steel, or synthetic material.

Lubrication is essential to ensure the proper function of cylindrical roller bearings. Grease or oil is used to reduce friction and heat generated by the bearing, prolonging its lifespan and improving its overall performance.

Uses of Cylindrical Roller Bearings Cylindrical roller bearings are widely used in various industries, including:

Electric Motors Cylindrical roller bearings are commonly used in electric motors to support the rotor and handle radial loads. They are often used in motors with high radial loads, such as those used in industrial applications.

Gearboxes Cylindrical roller bearings are often used in gearboxes to support the gears and handle radial loads. They are particularly useful in applications where space is limited, as they can support heavy loads without taking up too much space.

Machine Tools Cylindrical roller bearings are used in machine tools such as lathes and milling machines to support the spindle and handle radial loads. They are preferred over other types of bearings because they can handle heavier loads and provide greater stiffness and accuracy.

Paper Machines Cylindrical roller bearings are used in paper machines to support the rollers and handle radial loads. They are particularly useful in applications where high speeds and heavy loads are involved.

Railway Applications Cylindrical roller bearings are used in railway applications to support the wheels and handle radial loads. They are preferred over other types of bearings because they can handle high speeds and heavy loads.

In summary, cylindrical roller bearings are a critical component of many industrial applications. They are designed to handle high radial loads and moderate thrust loads and are widely used in industries such as electric motors, gearboxes, machine tools, paper machines, and railway applications. With their various components working together, cylindrical roller bearings can support heavy loads, reduce friction, and ensure the smooth operation of machinery.

Cylindrical Roller Bearing Features

-

01

Roller and raceway are in linear contact or curved contact after modification, with large radial bearing capacity, suitable for bearing heavy loads and impact loads.

-

02

The friction coefficient is small, suitable for high speed, and the limit speed is close to the deep groove ball bearing.

-

03

The N type and NU type can move axially, can adapt to the change of the relative position between the shaft and the housing caused by thermal expansion or installation error, and can be used as a free end support.

-

04

The processing requirements for the shaft or the seat hole are high, and the relative deflection of the outer ring axis after the cylindrical roller bearing is installed must be strictly controlled to avoid contact stress concentration.

-

05

The inner ring or outer ring can be separated for easy installation and disassembly.

Cylindrical Roller Bearing VS Deep Groove Ball Bearing

The main difference between the two types of bearings lies in rolling elements, one is spherical rolling element, the other is cylindrical rolling element. It is precisely because the following differences between them have occurred.

-

Different bearing capacity

The contact surface of spherical rolling element and cylindrical rolling element is different. The spherical contact surface is a point, while the cylindrical contact surface is a line. Therefore, under the same size, the radial bearing capacity of cylindrical roller bearings is greater than that of deep groove ball bearings.

-

Different speeds

Because the contact surfaces of the rolling elements of the two bearings are different, their speeds are also different. The larger the contact surface is, the slower the relative speed is. Therefore, deep groove ball bearings with spherical rolling elements have an advantage in speed.

-

The noise is different

When the speed of the bearing of the same size is the same, the noise of the cylindrical roller bearing is greater than that of the deep groove ball bearing. This is also because the friction caused by the different contact surfaces of the rolling elements of the two bearings is different. The greater the friction surface, the greater the noise.

The difference between them is due to their different rolling elements. This also confirms one thing: every component in the bearing is an important part of its overall structure. Bearing products are composed of different structures and different components have different characteristics.

English

English