Crossed roller bearings have various structures: inner ring or outer ring which is divided into two halves, and inner ring and outer ring as a whole with high rigidity. The two-half split structure is fastened together by bolts or rivets at the factory to prevent separation during the transportation and installation. Since the rollers are arranged in a cross, only one set of Cross Roller Rings can withstand loads in all directions, and the rigidity is 3 to 4 times higher than that of conventional models. At the same time, since the inner ring or outer ring of the crossed roller bearing is divided into two structures, the bearing clearance can be adjusted, and even if a preload is applied, high-precision rotational motion can be obtained. Moreover, due to its special structure, it is usually used as a joint bearing in industrial robots. As a professional cross roller bearing supplier, THB-bearings has its own cross roller bearing factory which ensures the quality of our products. We can offer you two types of cross roller bearings including crossed cylindrical roller bearings and crossed tapered roller bearings with high quality. You can click and check more details below.

-

Products

- Track Roller

- Deep Groove Ball Bearing

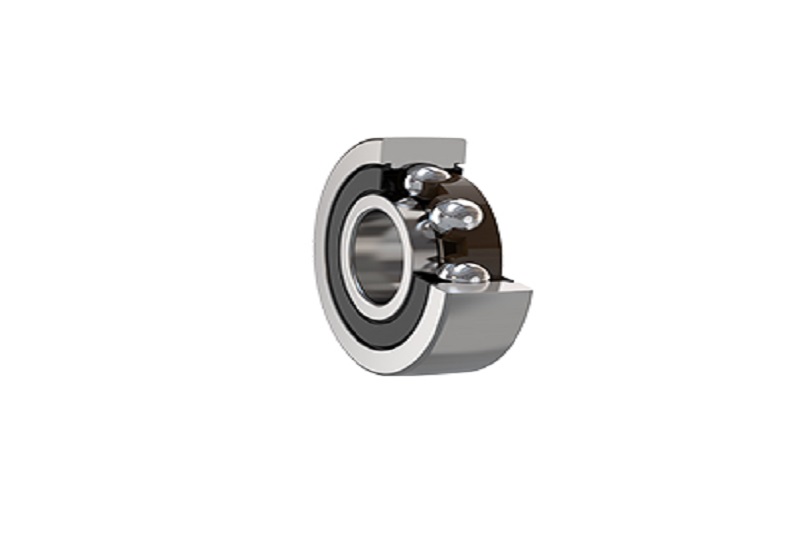

- Self-aligning Ball Bearing

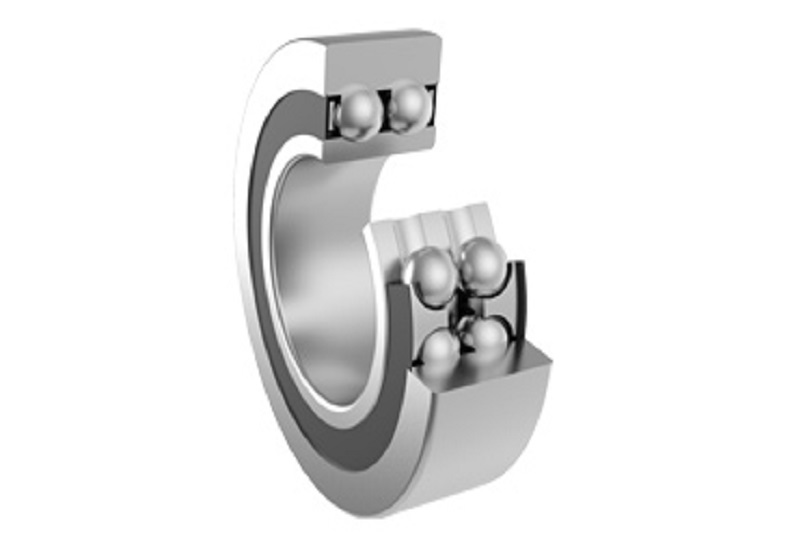

- Angular Contact Ball Bearing

- Thrust Ball Bearing

- Needle Roller Bearing

- Cylindrical Roller Bearing

- Spherical Roller Bearing

- Tapered Roller Bearing

- Thrust Roller Bearing

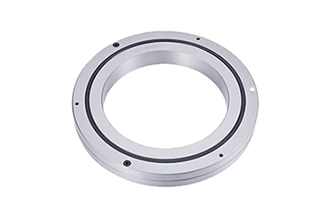

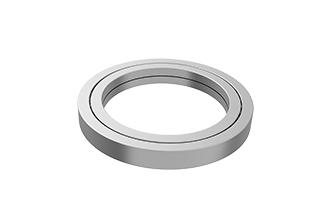

- Crossed Roller Bearing

- Slewing Ring

- Pillow Block Bearing

- Plain Bearing

- Track Roller

- Industries

- Technical Service

-

Knowledge Center

- Company

- News

- Contact Us

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano