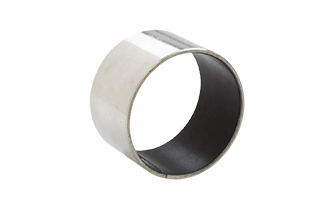

Various bushings could be made with different materials. By different materials and structures, bushings could be divided into: solid bronze cylindrical and flange bushings, sintered bronze bushings, rolled bronze bushings, PTFE composite bushings, POM composite bushings, PTFE nylon bushings, etc., which are suitable for a variety of working conditions. Self lubricating bushing bearings, created by THB, one of the most professional self lubricating bearings manufacturers in China, are of high quality.

As one of the top plain bearing manufacturers in the industry, we are committed to providing products that meet the highest standards of performance and reliability. Our team of experts is always ready to assist you in selecting the right bearings for your specific applications. Trust THB Bearings for all your plain bearing needs. Our extensive inventory ensures that you can find the perfect bearing for your needs, whether you require standard options or a custom plain bearing solution.

Features of Self-lubricating Bearings

They can be used for rotation, reciprocation and linear motions, but cylinder-shaped bushings could only carry radial loads.

Flanged bushings are could carry radial loads and the axial loads in one direction.

Lubricating materials can be added inside the bushings through processes such as material porosity and material sintering, realizing achieving self-lubricating.

Applications of Self-lubricating Bearings

| Mechanical transmission | printing and dyeing | paper making | petroleum | metallurgy |

| food and beverage machinery | engineering machinery | chemicals | automotive | / |

Self-lubricating bearings are designed to operate without the need for external lubrication, making them ideal for a wide range of applications where maintenance is challenging or where lubrication is impractical.

Automotive Industry:

Steering Systems: Used in steering columns and linkages to reduce friction and wear.

Suspension Systems: Applied in shock absorbers and suspension joints for smooth operation.

Transmission Systems: Utilized in gearboxes and clutches to enhance performance and longevity.

Aerospace Industry:

Landing Gear: Essential for reducing friction and wear in landing gear mechanisms.

Control Surfaces: Used in ailerons, rudders, and elevators to ensure smooth and reliable movement.

Engine Components: Applied in various engine parts to withstand high temperatures and loads.

Industrial Machinery:

Conveyors: Ideal for conveyor systems in manufacturing plants to ensure continuous operation.

Pumps and Compressors: Used in pumps and compressors to reduce maintenance and downtime.

Textile Machinery: Applied in looms and other textile machinery for smooth and efficient operation.

Agricultural Equipment:

Tractors and Harvesters: Used in various moving parts to reduce maintenance and improve reliability.

Irrigation Systems: Applied in pivot points and joints to ensure smooth operation without frequent lubrication.

Medical Devices:

Imaging Equipment: Used in MRI and CT scanners to ensure precise and smooth movement.

Surgical Instruments: Applied in various surgical tools to reduce friction and enhance performance.

Prosthetics: Utilized in artificial joints and limbs for long-lasting and maintenance-free operation.

Renewable Energy:

Railway and Transportation:

Marine Industry:

Construction Equipment:

Food and Beverage Industry:

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano