【Food And Beverage Industry】Food Packaging Equipment Technical Service Solutions

Pain Points of Clients

1. The factors that shorten the service life of the food packaging equipment:

Reciprocating linear motion;

Rapid starting and stopping;

frequent direction changes;

2. Frequent stopping affects production efficiency.

Optimized Solution Provided by THB

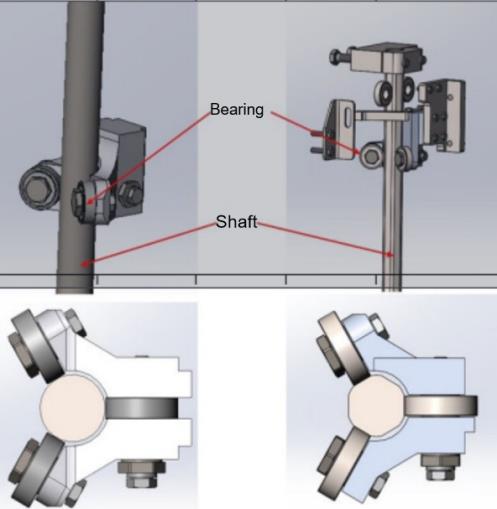

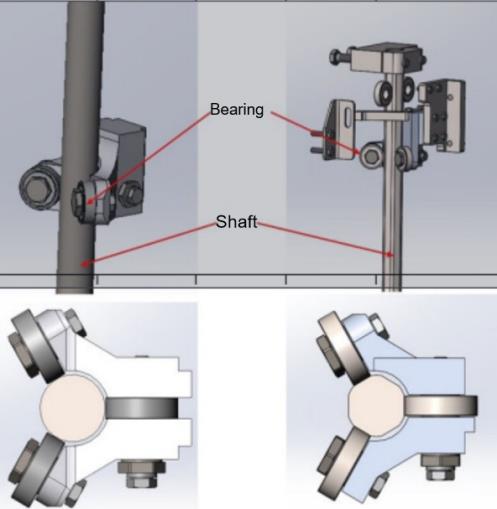

1. Based on the conditions of the client's equipment and usage, we optimized the shape of the mechanism support track (roller

bar) by changing it from cylindrical to hexagonal so that the contact surface between the bearing and the support track is upgraded from point contact to linear contact, greatly reducing the contact stress and making the supporting more stable and reliable.

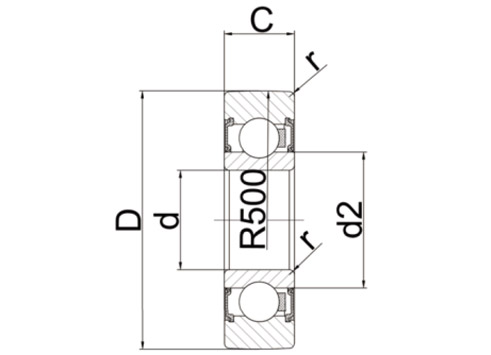

2. More suitable bearings were recommended by using LR series ball roller bearings instead of deep grove ball bearings as the supporting bearings. The outer ring design with a thick wall could increase the rigidity of the outer ring when it is rolling in the raceway, to reduce the influence of its elastic deformation on the bearing internal force state and improve the service life.

Benefits for Clients

The optimization of the mechanism and bearings reduced the maintenance downtime and component replacement cost for the client, and significantly improved the performance of the equipment.

The maintenance interval of the bearing tracks of the client was increased to more than 1 year from 3 months, and the service life of the bearings was increased to more than 2 years from 3 months. The maintenance cost of the client was reduced by more than 70% and the equipment efficiency was improved by more than 30%.

Diagram of Components of Food Packaging Equipment

Static Stress-strain And Dynamic Life Analysis

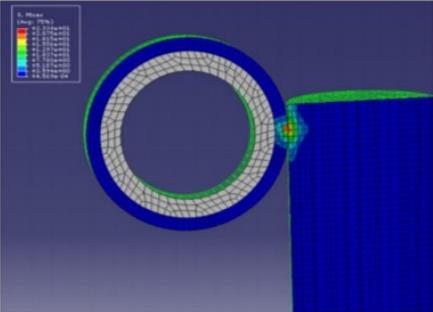

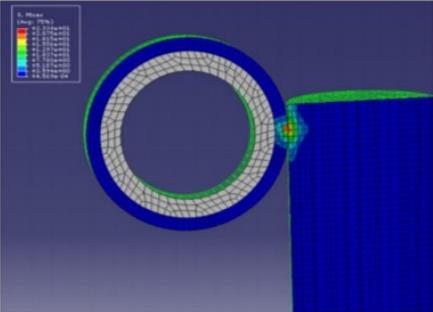

1. Stress-strain Analysis

A simple analysis of the shaft system using finite element software reveals that the stress in thecontact area between the outer ring of the bearing and the shaft is large, which shall be calculated.

To obtain the calculation results of the two solutions:

| Solution | Configuration details | Contact deformation (um) | Maximum contact stress (Mpa)

|

| Solution 1 | Cylindrical shaft with 6001 bearing | 9.7 | 1934 |

| Solution 2 | Hexagonal shaft with LR6001 bearing | 4.4 | 698 |

According to the analysis results, the contact stress and deformation of Solution 1 with cylindrical shaft and standard 6001 bearing are much higher than those of Solution 2 with hexagonal shat and LR6001 bearing.

2. Dynamic Life Measurement

| Solution | Effective rated dynamic load (N) | Simulated dynamic load (N) | Reciprocal stroke (m) | Reciprocation times | Bearing outer diameter | Rotational speed (RPM) | Calculated service life (h) |

| Solution 1 | 2700 | 500 | 0.6 | 0.9 | 28 | 454.7 | 5771.357032 |

| Solution 2 | 4200 | 500 | 0.6 | 0.9 | 30 | 424.4 | 23275.43165 |

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano