In the realm of mechanical engineering and machine component design, the efficacy and reliability of machine elements are paramount. Amongst these essential elements, the bearing stands out as a critical component that ensures the smooth operation of machinery. Specifically, the grooved roller bearing, a specimen of precision and durability, offers a broad spectrum of benefits to machinery performance. THB Bearings, a brand synonymous with quality and innovation, has been at the forefront of designing bearings that significantly contribute to the enhanced performance of machinery in various sectors.

Understanding Grooved Roller Bearings

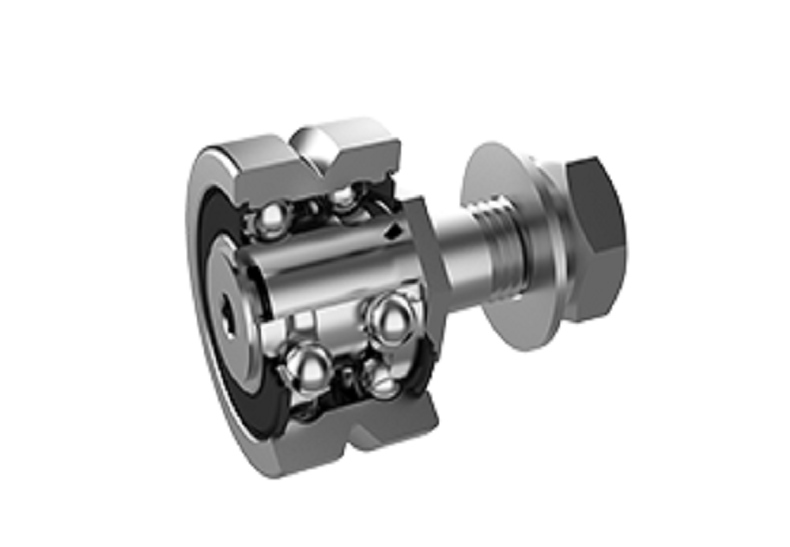

Before diving into the benefits of grooved roller bearings, it’s crucial to understand what they are. Essentially, these are types of roller bearings designed with grooves in the outer and sometimes the inner ring, which allows for the rolling elements to be accurately guided. This design innovation enables the bearing to withstand both radial and axial loads, making it a versatile solution for many applications.

Enhanced Load Capacity

One of the most significant advantages of grooved roller bearings is their ability to handle heavier loads compared to their plain counterparts. The presence of grooves provides a larger contact area for the rolling elements within the bearing. This not only distributes the load more evenly but also reduces stress concentration, which in turn, extends the bearing's life. THB Bearings has capitalized on this feature to engineer bearings that cater to industries where heavy load capacity is crucial, like in construction equipment and heavy machinery.

Improved Precision and Control

The design of grooved roller bearings offers superior precision and control in operational activities. The grooves ensure that the rolling elements are aligned perfectly, thereby reducing the chances of skewing and misalignment which are common issues in high-speed applications. This precision is critical in industries such as automotive and aerospace, where even the slightest deviation can lead to significant performance degradation or safety concerns. THB Bearings' emphasis on precision manufacturing means their grooved roller bearings are highly sought after for applications where control and accuracy are paramount.

Reduced Friction and Heat Generation

Friction and heat generation are two factors that significantly affect machinery performance. Excessive heat can lead to material degradation, lubricant breakdown, and ultimately, premature bearing failure. Grooved roller bearings, with their well-defined pathways for rolling elements, minimize friction and, consequently, heat generation. This not only boosts the efficiency of machinery but also contributes to energy savings and lowers maintenance needs. THB Bearings designs its grooved roller bearings to have optimal surface finish and clearance specifications, ensuring minimal friction and extending the operational life of the machinery.

Versatility Across Applications

The adaptability of grooved roller bearings to various operational conditions makes them a preferred choice across a wide range of applications. Whether it’s the high-speed requirement of electric motors, the precision of CNC machinery, or the durability demands of mining equipment, grooved roller bearings can be engineered to meet diverse operational needs. THB Bearings has a portfolio of grooved roller bearings that cater to these varied applications, showcasing their versatility and performance enhancement capabilities.

Enhanced Durability and Reliability

Durability and reliability are the hallmarks of any high-quality bearing. Grooved roller bearings, with their robust design, can withstand harsh operating conditions, including high loads, vibrations, and temperature fluctuations. This resilience translates to less downtime, reduced maintenance costs, and a longer service life for the machinery. THB Bearings' commitment to using high-quality materials and state-of-the-art manufacturing processes ensures that their grooved roller bearings set the standard for durability and reliability in the industry.

The incorporation of grooved roller bearings into machinery design brings about a substantial improvement in performance. From enhanced load capacity and precision to reduced friction and broad application scope, these bearings offer a comprehensive solution to many engineering challenges. THB Bearings, with its focus on quality and innovation, continues to provide grooved roller bearings that meet and exceed the performance expectations in various sectors. As technology progresses, THB Bearings remains dedicated to advancing their offerings, ensuring that machinery performance is continuously enhanced through the use of high-quality grooved roller bearings.

English

English