We Are Glad To Inform That We Changed Our Company Logo In 12th June 2020.

We want to convey our vision of the future with the new logo. We believe the future industrial production will change to be a higher and higher level of “automation, digitalization and intellectualization”. Any shutdown of the production for any reason can cost very much.THB is investing more and more to have new technology to make the bearing have a longer lifetime than normal or maintenance-free. THB is presenting more and more technology to help customers to save costs from their production.

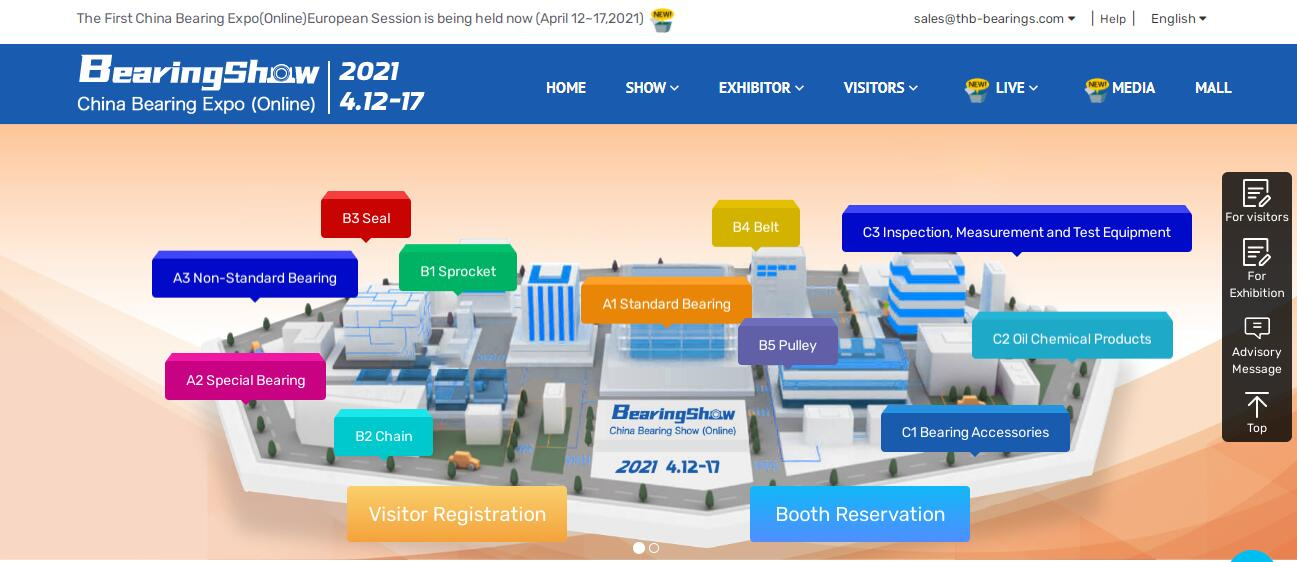

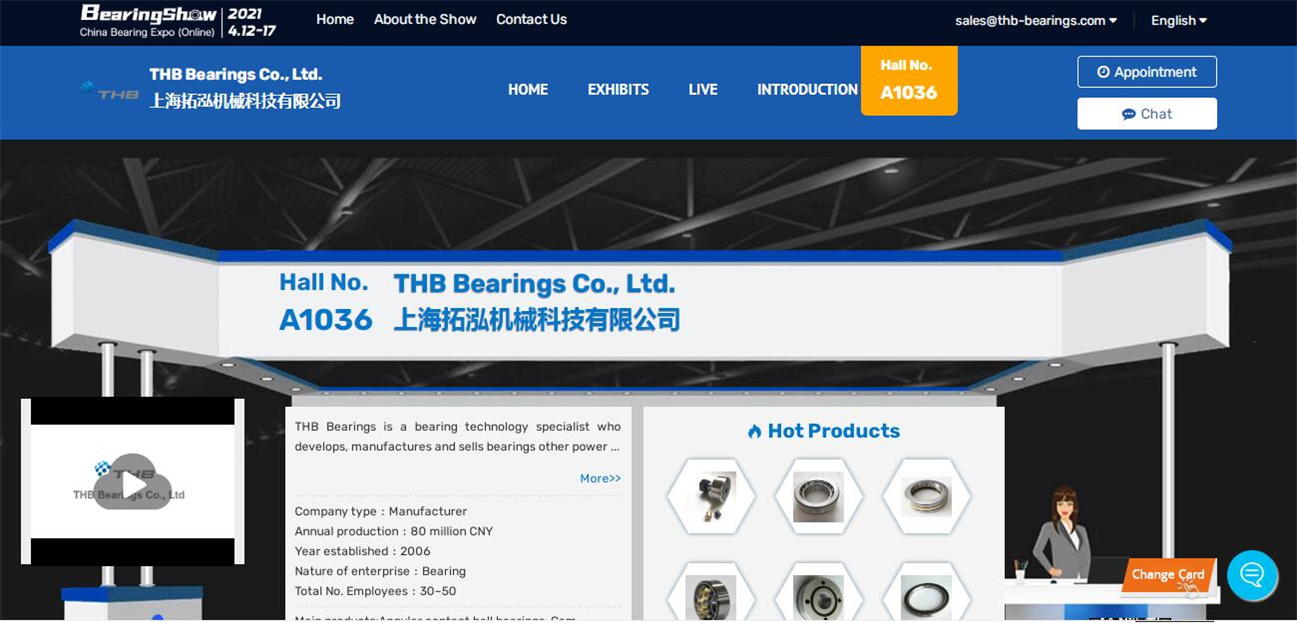

2021 China Bearing and Power Transmission Show(Online)- 12 to 17 April 2021

Cause of COVID-19, online show is a new trend. We participated in our first online exhibition, this is a new experience for THB.

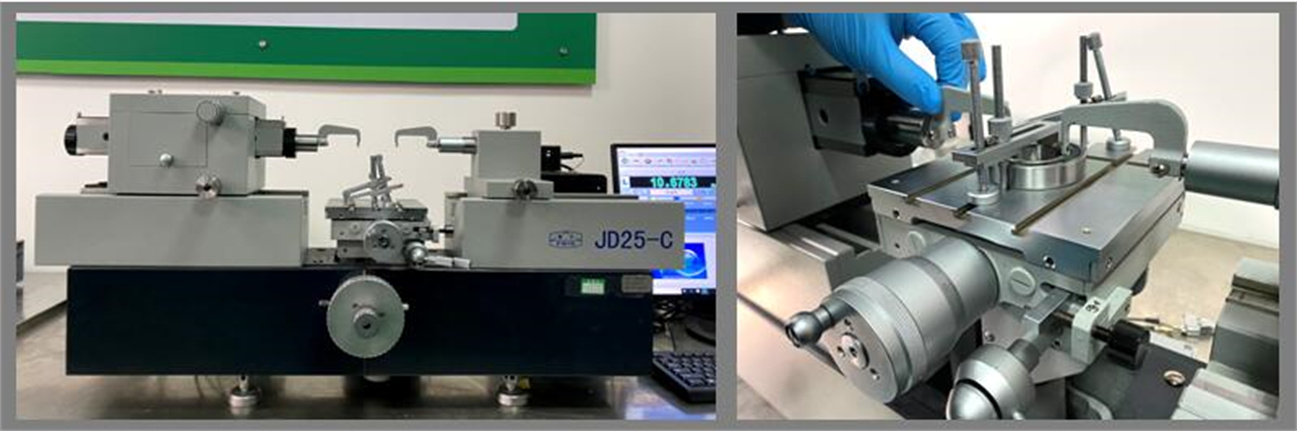

Good quality control helps companies meet customer demands for better products.

In order to get a better guarantee of product quality. THB bought advanced testing equipment in 2020&2021

For example:

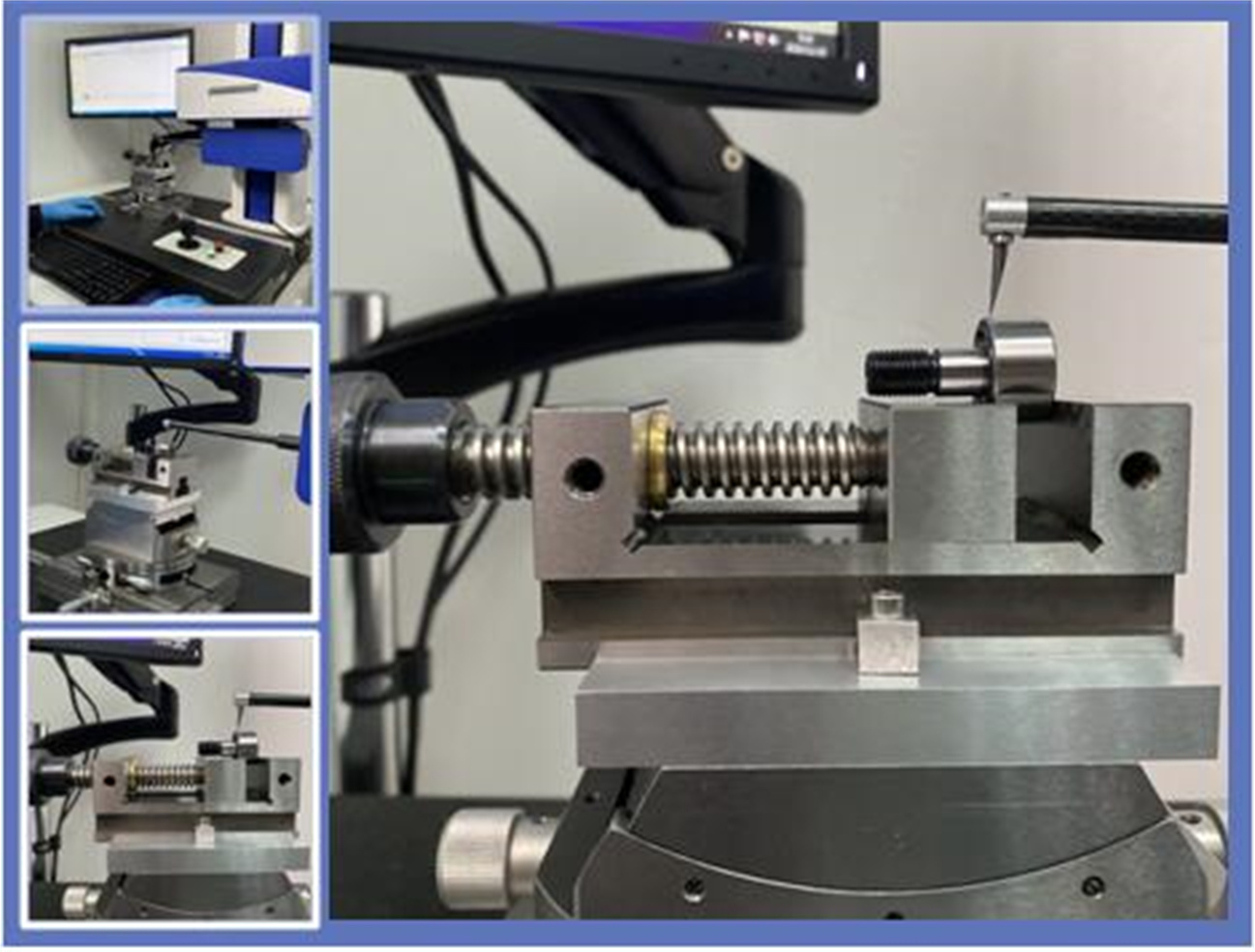

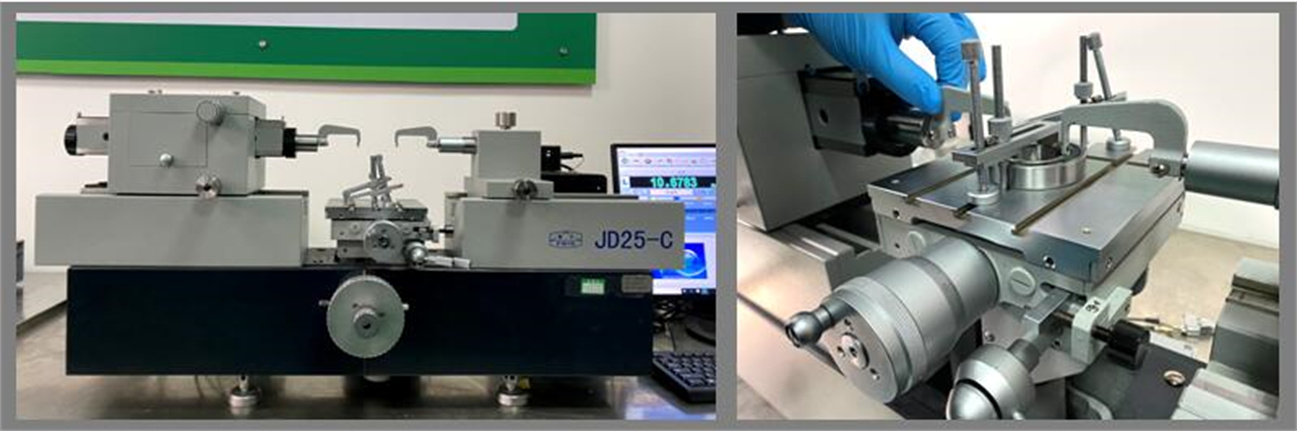

一.Digital Universal Length Measurer

Type: JD25-D / JD25-C

Application:

Digital universal length measurer is a kind of length measuring instrument which is used in the absolute and comparative measurement. It is mainly used in the metal-processing industry, especially those measuring rooms or inspection stations of the machinery industry and other industrial fields, such as tool-measure and instruments manufacturing.

Features:

Good stability after long-term natural seasoning.

Optimization design, high performance and precision.

It is equipped with an optical grating measuring system, the measuring result is displayed in numbers visually.

High measuring precision.

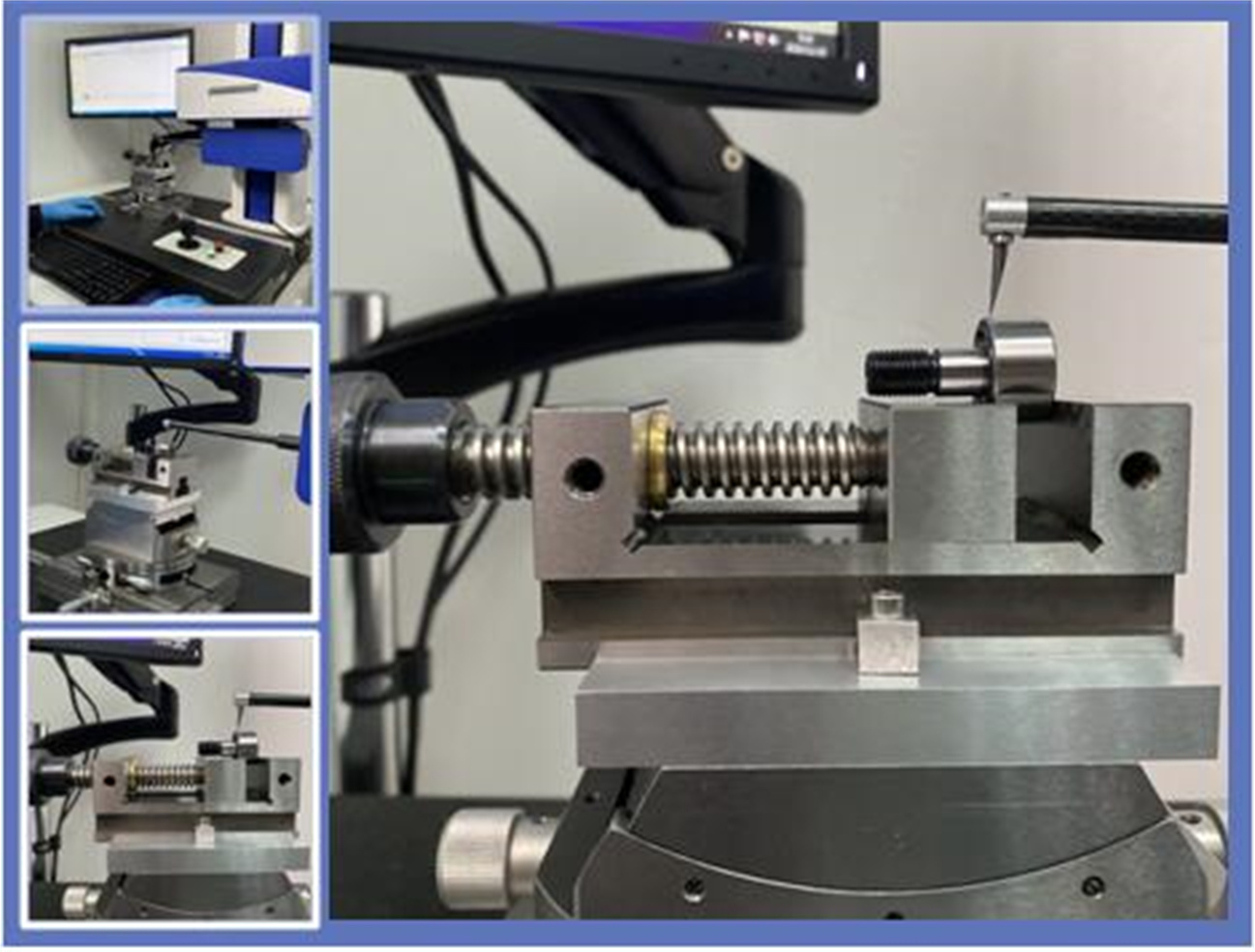

Roughness profile integrated machine

Type: MMD-HPG100F

Features:

The profile roughness is integrated to realize the primary measurement, and the profile and roughness are analyzed simultaneously

The roughness measurement sensor is an imported grating sensor, which has a large measuring range.

The first measurement can analyze the roughness of different areas of the workpiece. Improve measurement efficiency.

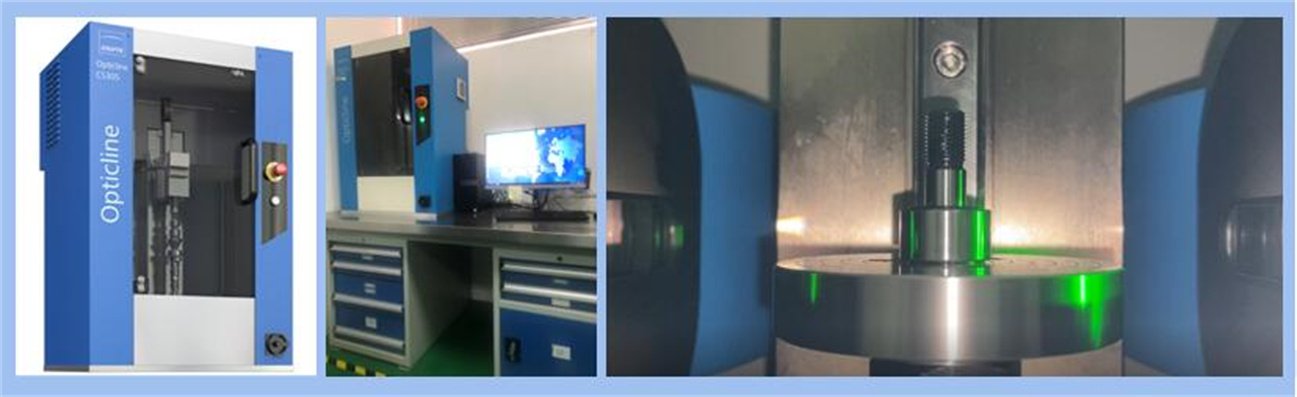

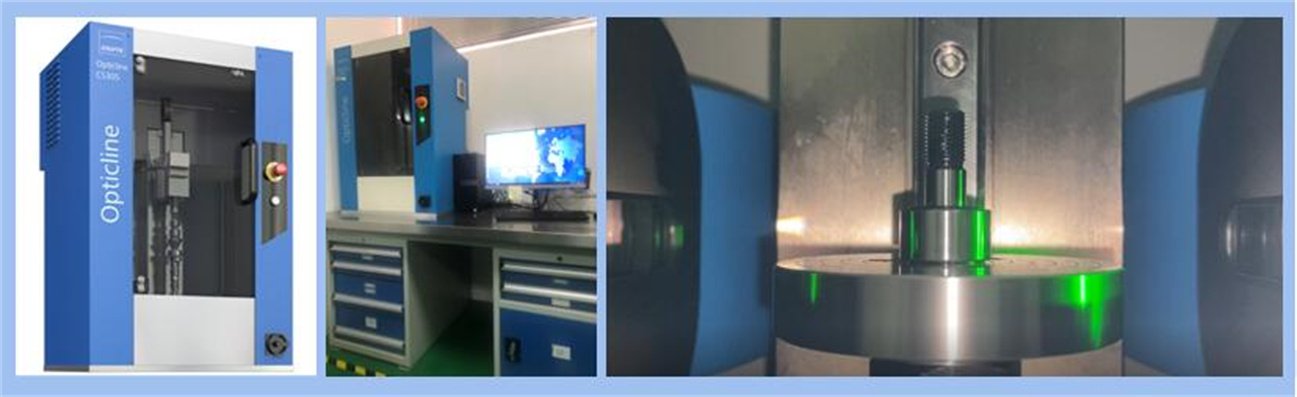

CS measuring stations

Type: Opticline CS308

Fitted with various interfaces for statistical process control (SPC) the Opticline CS systems allow extremely efficient monitoring of the manufacturing process and allow rapid intervention where necessary. This ensures that you can produce turned parts of consistently high quality. The measuring systems are simple to operate, allow non-operator-dependent measurement results, and deliver easy to understand measurement results with analysis functions where required.

Benefits

Easy, fast and flexible measurements

Automated measuring runs

Statistics capable and conclusive reporting

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano