Seamless Operations: Custom Track Roller Bearings in Conveyor Systems

In the industrial world, where efficiency and reliability are non-negotiable, the need for precision-engineered components can make or break the success of conveyor system operations. One essential component that often flies under the radar, yet plays a pivotal role in the seamless operation of conveyor systems, is the track roller bearing. Especially when it comes to custom solutions, finding the right partner to deliver on specific requirements is paramount. This is where THB Bearings stands out, offering custom track roller bearings that are designed to meet the unique needs of various conveyor systems, ensuring smooth operations and extended lifespan of the machinery.

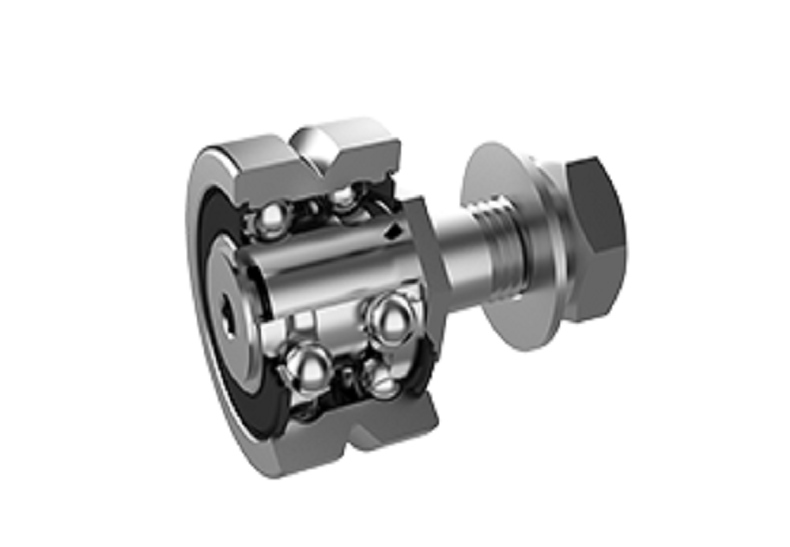

The Critical Role of Track Roller Bearings in Conveyor Systems

Track roller bearings are at the heart of conveyor systems, facilitating the smooth and efficient movement of goods across various stages of the production or distribution process. They are designed to bear heavy loads, resist contamination, reduce friction, and provide excellent mobility, making them indispensable for the optimal functioning of conveyor systems. The efficiency and reliability of a conveyor system heavily rely on the performance of these bearings. Therefore, choosing high-quality custom track roller bearings is crucial for industrial applications.

Customization: Tailoring to Specific System Requirements

Every conveyor system has its own set of unique challenges and requirements based on the nature of the materials being handled, the environment in which the system operates, and the specific operational demands. This is where the concept of custom track roller bearings comes into play. THB Bearings specializes in creating tailor-made bearing solutions that perfectly match the requirements of any conveyor system. Whether it's variations in size, load capacities, materials, or even specific design features to handle extreme temperatures or corrosive environments, THB Bearings' custom approach ensures that every aspect of the bearing is optimized for its intended use.

How Custom Track Roller Bearings Enhance Operations

Improved Efficiency: By perfectly matching the specifications of the conveyor system, custom track roller bearings minimize friction and energy use, resulting in smoother operations and potentially lower energy costs.

Choosing THB Bearings for Your Custom Needs

When it comes to selecting a partner for your custom track roller bearing needs, several factors set THB Bearings apart:

Expertise and Experience: With years of expertise in bearing design and manufacturing, THB Bearings possesses the necessary knowledge to craft high-quality, durable bearings for any application.

Customization Capabilities: THB Bearings' state-of-the-art manufacturing process can accommodate a wide range of custom specifications, ensuring that each client receives the perfect solution for their conveyor system.

Quality Assurance: Sticking to rigorous quality control measures, THB Bearings guarantees that every custom track roller bearing meets the highest standards of performance and durability.

Customer-Centric Approach: Understanding that no two operations are alike, THB Bearings prioritizes customer needs and works closely with them to develop bespoke solutions that drive their conveyor systems' efficiency and reliability.

In the fast-paced industrial environments where conveyor systems play a critical role in day-to-day operations, the importance of every component, especially track roller bearings, cannot be overstated. Opting for custom track roller bearings from THB Bearings not only ensures that your conveyor systems operate at peak efficiency but also contributes to longer operational lifespans, reduced maintenance requirements, and ultimately, lower operational costs. Make the right choice for your conveyor systems and ensure smooth, uninterrupted operations with THB Bearings' custom solutions.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano