The Most Precise Motion Control Method——Roller Driver and Its Bearing Recommendation

Roller Driver is one of the most precise motion control methods currently. It has a wide range of applications, including auto parts, 3C, five-axis machining centers and other conditions that require high-precision motion control.

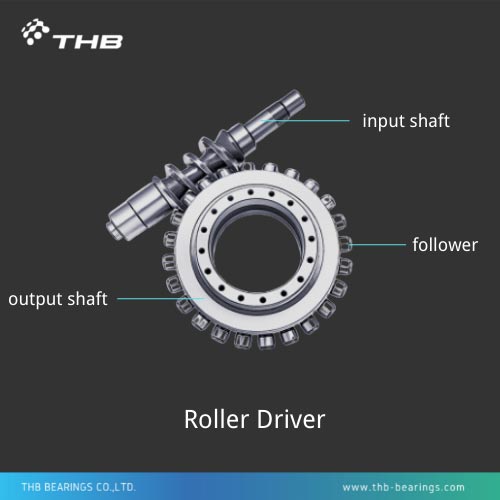

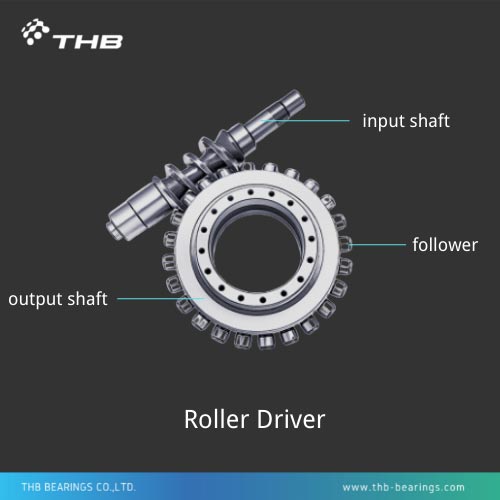

The composition of the Roller Driver includes an input shaft (curved high-precision indexing cam) and an output shaft (turret). The cam follower roller element on the output shaft, that is, the bearing, engages in line contact with the surface of the cam groove on the input shaft.

The characteristics of Roller Driver:

Zero backlash, high precision

Rolling transfer, high efficiency, fast positioning (short indexing time)

High rigidity

Maintenance-free, long service life

Bearing recommendation in Roller Driver

roller bearings,needle roller bearings,track rollers,crossed roller bearings and tapered roller bearings.

- Selecting the appropriate bearing can effectively improve the stiffness of the roller driver, thereby solving the problem of low precision of the finished product of the overall mechanism.

- There is rolling contact between the precision bearing and the cam, and the friction loss is small, which improves the transmission efficiency and accuracy, and solves the problem of low life of the overall mechanism

In order to better meet the zero clearance and high-precision transmission requirements of the overall mechanism, it is first necessary to select high-precision bearings, and then the following three points need to be considered:

- Adopt the outer contour of the cam bearing adaption group

- Adjust bearing radial clearance to improve rotational accuracy and rigidity

- Provide suitable installation tolerance and assembly method

THB can provide you with rationalized suggestions on the design and manufacturing process of precision rotary tables, reliable bearing products and bearing application solutions. If you want to know more, please feel free to contact us.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano