What is the Difference Between a Slewing Bearing and a Turntable Bearing?

What Is a Slewing bearing?

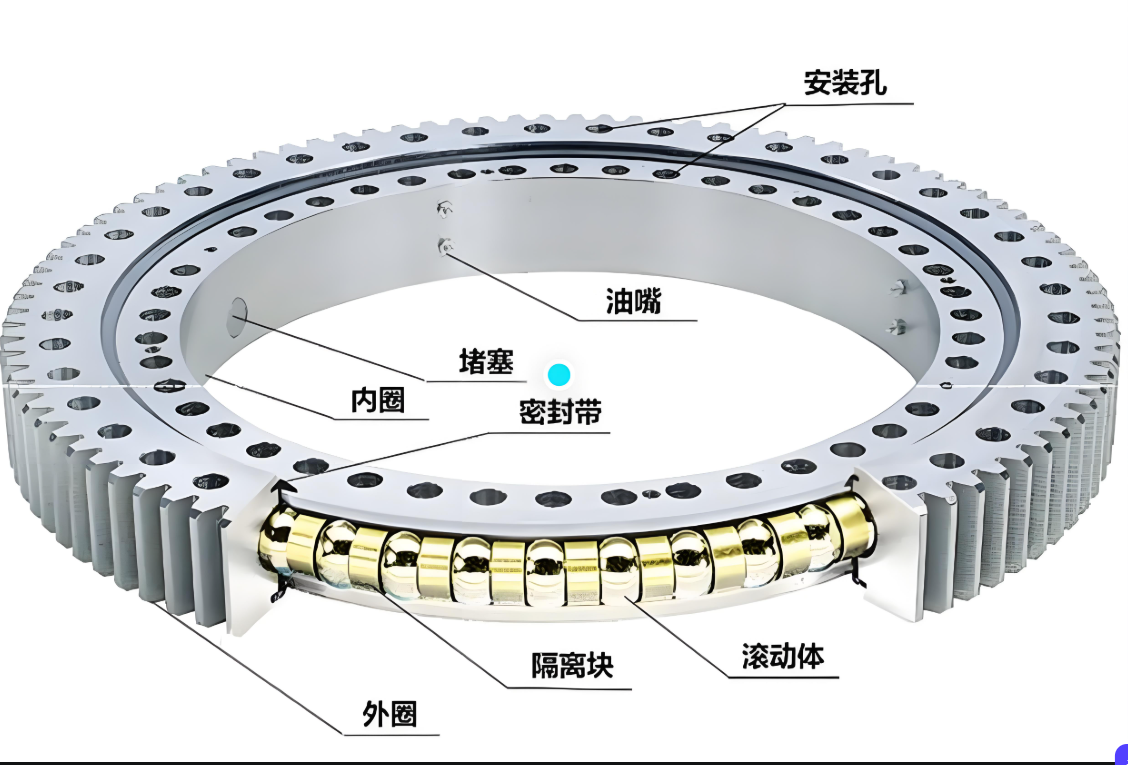

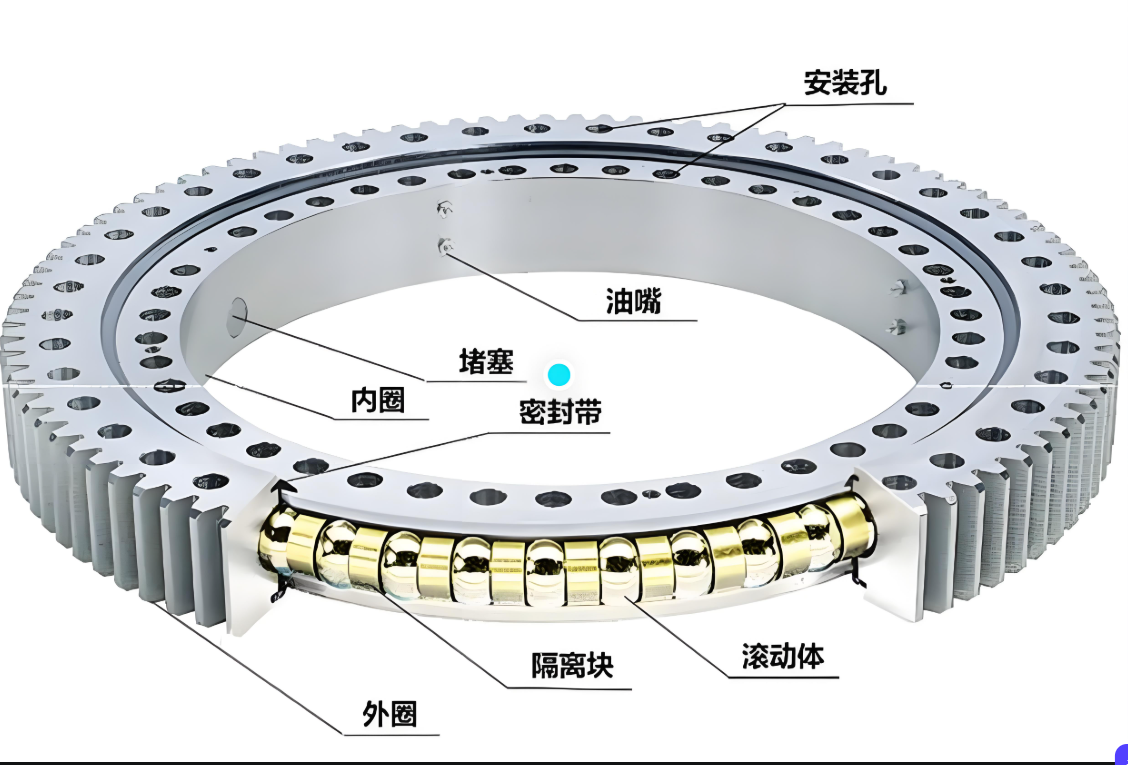

The slewing bearing is a new type of mechanical parts, which consists of inner and outer rings, rolling bodies, etc. The slewing bearing is a large bearing that can accept comprehensive loads, and can simultaneously accept large axial and radial loads and overturning moments.

Inner and Outer Rings: Slewing bearings consist of an inner ring and an outer ring, which are usually made of high-strength steel.

Rolling Elements: Between the rings, there are rolling elements such as balls or rollers that facilitate smooth rotation.

Gear Teeth: Many slewing bearings come with gear teeth on either the inner or outer ring, allowing them to be integrated with drive mechanisms for powered rotation.

What Is a Turntable bearing?

Turntable bearing is a kind of large bearing with special structure that can accept large axial load, radial load and overturning moment and other comprehensive loads at the same time, and integrates various functions such as support, rotation, transmission and fixation.

Concentric Rings: Turntable bearings consist of two concentric rings, usually made of metal or plastic.

Rolling Elements: Between the rings, there are rolling elements such as ball bearings or rollers that allow for smooth rotation.

Low Profile: These bearings often have a low profile, making them suitable for applications where space is limited.

Slewing Bearing VS. Turntable Bearing

| Feature/Parameter | Turntable Bearings | Slewing Bearings |

| Advantages | 1. Simple design and easy to install.

2. Cost-effective for light-duty applications.

3. Low maintenance requirements. | 1. High load-carrying capacity, capable of handling complex loads.

2. Versatile, can be used in both horizontal and vertical orientations

3. Available in various configurations, including single-row, double-row, and triple-row designs. |

| Disadvantages | Limited load-carrying capacity, not suitable for heavy-duty or high-precision applications. | 1. More complex and expensive.

2. Requires more maintenance and precise installation. |

| Load Capacity | Suitable for light to moderate loads. | Designed for heavy-duty applications with high load capacities. |

| Complexity and Cost | Simple design, cost-effective. | More complex and expensive, but offers greater versatility and load capacity. |

| Application Scenarios | Light-duty, less demanding applications. | Heavy machinery and equipment requiring robust performance and high load capacity. |

| Orientation | Typically used in horizontal applications. | Can be used in both horizontal and vertical applications. |

What is the difference between the structure of the slewing support and the turntable support?

Slewing bearing structure

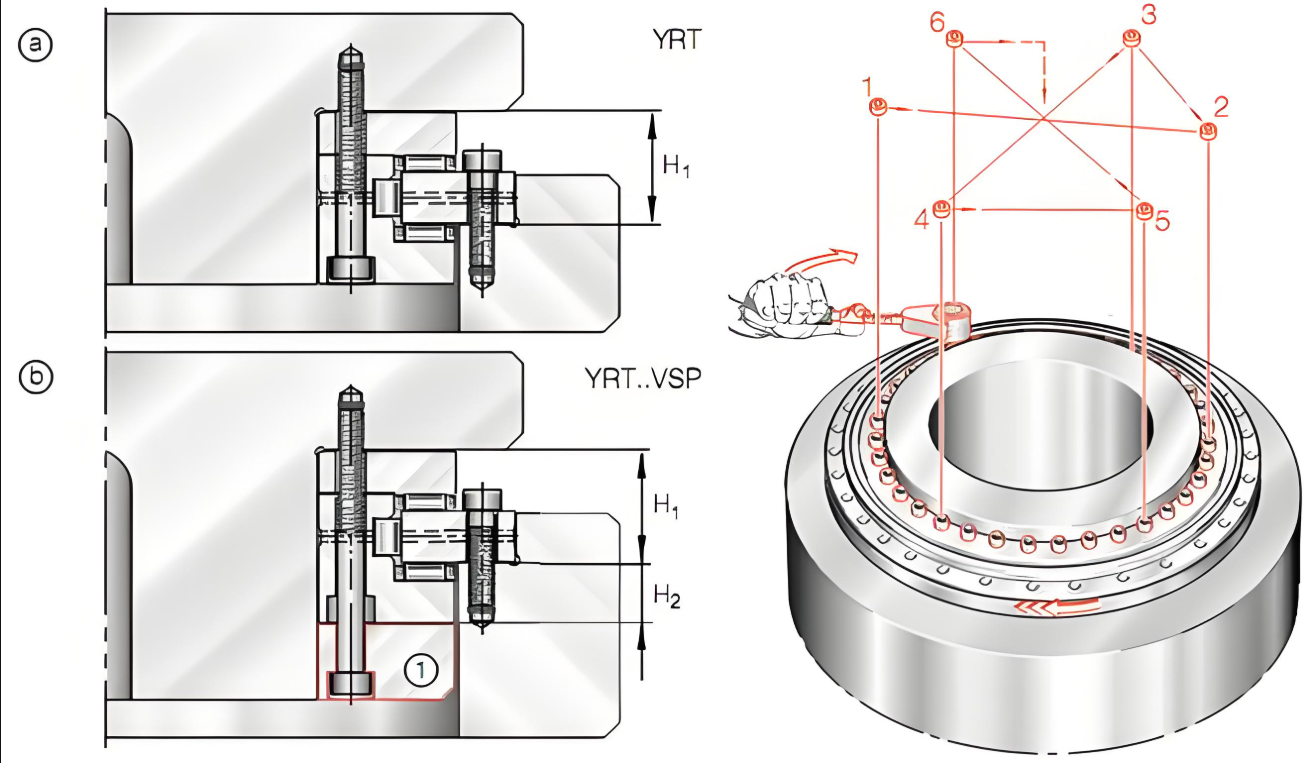

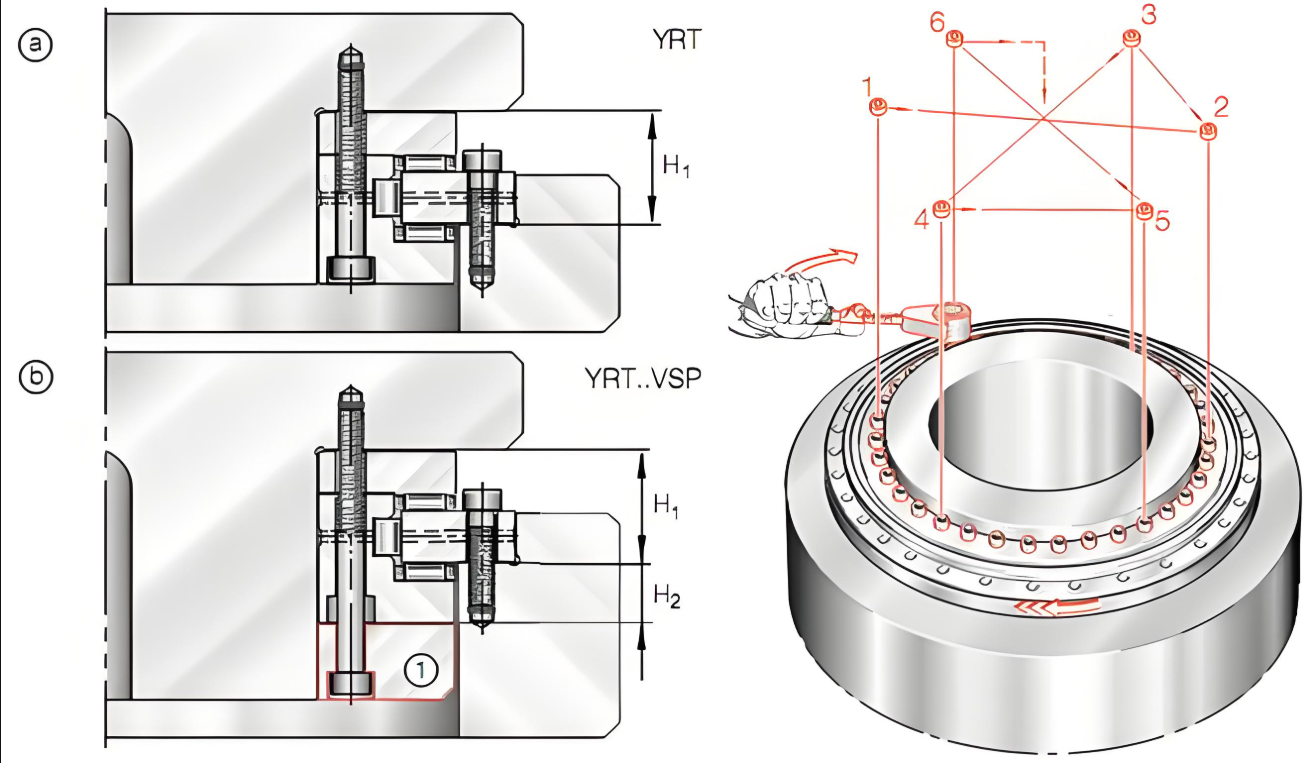

Slewing bearing is generally composed of worm, slewing bearing, housing, motor and other components. Because the core components use slewing bearings, they can accept axial force, radial force and tipping moment at the same time. There are many forms, but the structure is basically the same.

Turntable bearing structure

The turntable bearing is generally composed of four major components: the inner ring, the outer ring, the rolling body, and the blocking block. Because the core components use slewing bearings, they can accept axial force and radial force at the same time. There are many forms, but the structure is basically the same.

What is the difference between the usage of the slewing bearing and the turntable bearing?

Slewing Bearing Application

Slewing bearings are widely used, and construction machinery is the first and widely used tools for slewing bearings, such as earth-moving machinery, excavators, disintegrators, stackers and reclaimers, graders, road rollers, dynamic compactors, rock drilling machinery, roadheaders, etc.

Others include concrete machinery: concrete pump truck, concrete mixing and placing boom integrated machine, belt placing machine Feeding machinery: disc feeder, sand mixer; hoisting machinery: wheel crane, crawler crane, door pedestal cranes, tower cranes, fork cranes, hoists, gantry cranes.

Ground treatment machinery: impact reverse circulation drilling rig, rotary drilling rig, impact rotary drilling rig, rotary drilling rig, reverse circulation rotary drilling rig, positive circulation rotary drilling rig, long spiral engineering drilling rig, diving engineering drilling rig, static pile driver, pile driver.

Engineering ships: dredgers; special vehicles: bridge inspection vehicles, fire trucks, window cleaning machines, flat beam transport vehicles, aerial work vehicles, self-propelled aerial work channels; light industrial machinery: beverage machinery, bottle blowing machines, packaging machinery, filling machine, rotary unscrambler, injection molding machine; marine crane: floating crane.

Turntable Bearing Application

Turntable bearings are widely used, and construction machinery is the place where turntable bearings are widely used, such as earth-moving machinery, excavators, disintegrators, stackers and reclaimers, graders, road rollers, dynamic compactors, rock drilling machinery, roadheaders, etc.

How Do I Choose a Slewing Bearing?

Choosing the right slewing bearing involves a thorough understanding of your application’s load requirements, environmental conditions, and operational parameters. By carefully considering these factors and consulting with bearing manufacturers or suppliers, you can select a slewing bearing that meets your needs and ensures reliable, long-term performance.

Types of Slewing Bearing for Sale

Four-point Contact Ball Slewing Bearing

Cross Roller Slewing Bearing

Three-row Roller Slewing Bearings

At THB Bearings, we pride ourselves on delivering top-quality slewing bearings designed to meet the diverse needs of our customers. Our extensive range includes single-row ball bearings, double-row ball bearings, crossed roller bearings, and triple-row roller bearings, each engineered for optimal performance and durability. Whether you require precision and rigidity for high-accuracy applications or maximum load capacity for heavy-duty machinery, THB Bearings has the perfect solution. Our slewing bearings are crafted from high-strength materials and are available with internal or external gear options to seamlessly integrate with your equipment. Trust THB Bearings for reliable, high-performance slewing bearings that keep your operations running smoothly. Explore our product line today and experience the THB difference!

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano