The Application of Plummer Bearing in AGV

In the bustling realm of Automated Guided Vehicles (AGVs), where seamless motion and precision are the lifelines, the humble yet robust component, the plummer bearing, emerges as an unsung hero. This blog aims to unravel the crucial role played by plummer bearings in AGV applications, exploring their unique features and indispensable contributions to the realm of automated mobility.

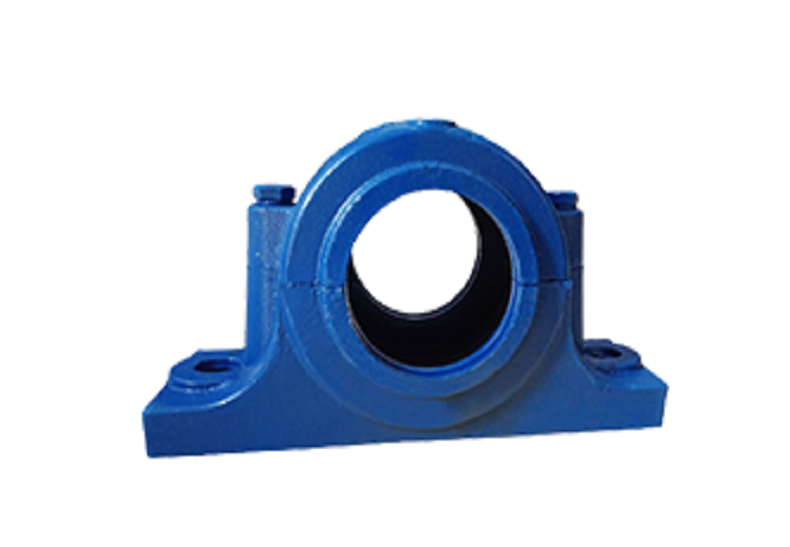

Unveiling the Design of Plummer Bearings

Before delving into their application in AGVs, it's essential to understand the design of plummer bearings. Also known as pillow block bearings, these components consist of a housing (plummer block) and a bearing. The bearing is typically spherical or cylindrical, housed within the robust and often split plummer block. This design not only provides stability but also facilitates easy installation and maintenance – characteristics that make plummer bearings ideal for AGV applications.

Essential Support for AGV Mobility

AGVs operate in dynamic environments, navigating through warehouses, production floors, and logistics centers. The support and mobility provided by plummer bearings are instrumental in ensuring the smooth and precise movement of AGVs. Whether it's steering mechanisms, wheel assemblies, or conveyor systems within AGVs, plummer bearings offer the necessary support, allowing these automated vehicles to navigate with agility and accuracy.

Load Distribution and Precision Steering

In AGV applications, where the ability to handle varying loads and maintain precise steering is critical, plummer bearings play a pivotal role. The robust housing of plummer bearings helps distribute loads evenly, preventing premature wear and ensuring the longevity of the bearing. This load distribution capability contributes to the overall stability of AGVs, allowing them to operate efficiently even in high-demand industrial settings.

Corrosion Resistance and Durability

AGVs are exposed to a range of environmental conditions, including moisture, dust, and temperature variations. Plummer bearings, often constructed from durable materials such as cast iron or stainless steel, offer corrosion resistance and durability. This ensures that AGVs equipped with plummer bearings can withstand challenging environments, contributing to their reliability and reducing the need for frequent maintenance.

Future Integration and Technological Advancements

As technology in AGV applications advances, so do the requirements for precision components like plummer bearings. Ongoing developments in materials, lubrication, and design contribute to improved performance and longevity. Innovations such as advanced seals and self-lubricating properties further position plummer bearings as critical components, driving the evolution of AGV systems.

In conclusion, the application of plummer bearings in AGV technology signifies a paradigm shift in precision engineering. From load distribution and durability to corrosion resistance and ease of maintenance, plummer bearings are indispensable for the seamless motion of AGVs. As AGV technology continues to evolve, the continued reliance on plummer bearings underscores their significance in shaping the future of automated material handling and industrial automation, proving that precision is indeed on the move with plummer bearings.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano