Yoke Type Track Rollers in Material Handling Equipment

When it comes to material handling equipment, efficiency and reliability are key. One component that plays a crucial role in the smooth operation of such equipment is the yoke type track roller. These rollers are designed to support and guide moving parts, allowing for easy and precise movement in a variety of applications. In this blog, we will explore the importance of yoke type track rollers in material handling equipment and how they contribute to the overall performance of the machinery.

What are Yoke Type Track Rollers?

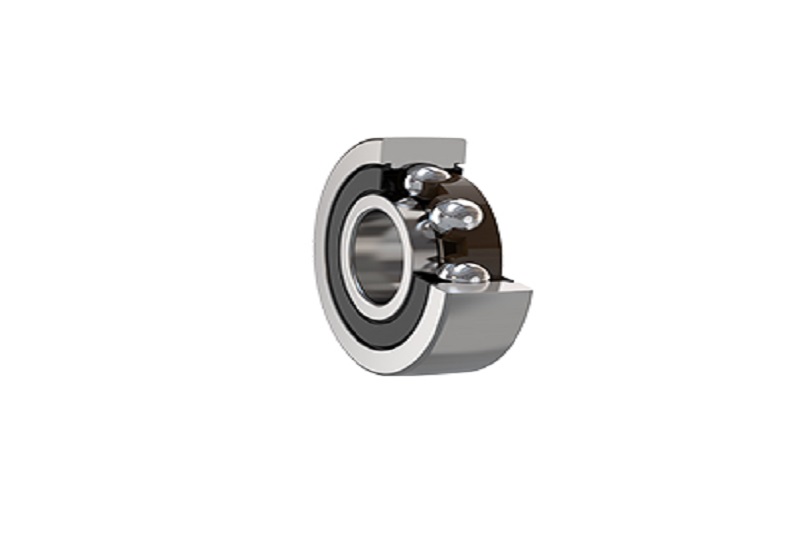

Yoke type track rollers are specialized bearings that are commonly used in material handling equipment such as conveyors, cranes, and hoists. They are designed to support heavy loads and provide smooth, consistent movement along a track or rail. The yoke design of these rollers allows for easy installation and alignment, making them a popular choice for a wide range of applications.

The Benefits of Yoke Type Track Rollers

One of the main benefits of yoke type track rollers is their ability to handle high loads and withstand heavy use. This makes them ideal for material handling equipment that operates in demanding environments. Additionally, yoke type track rollers are designed to reduce friction, which helps to minimize wear and extend the lifespan of the equipment they are used in.

Another key advantage of yoke type track rollers is their versatility. They are available in a variety of sizes and configurations, making it easy to find the right roller for any application. Whether you need a standard roller or a custom design, yoke type track roller bearing track can be tailored to meet your specific requirements.

Applications of Yoke Type Track Rollers

Yoke type track rollers are commonly used in a wide range of material handling equipment, including:

Conveyors: Yoke type track rollers are often used to guide the movement of conveyor belts, ensuring smooth and efficient transport of materials.

Cranes: Yoke type track rollers support the movement of crane trolleys along tracks, allowing for precise positioning and lifting of heavy loads.

Hoists: Yoke type track rollers are used to guide the movement of hoist chains or cables, ensuring reliable and consistent operation of the hoist.

Automated Guided Vehicles (AGVs): Yoke type track rollers are essential components of AGVs, providing the support and guidance needed for these vehicles to navigate safely and efficiently.

Overall, yoke type track rollers are an essential part of material handling equipment, providing support, guidance, and reliability in a wide range of applications.

In conclusion, yoke type track rollers play a critical role in the performance of material handling equipment, supporting heavy loads and ensuring smooth movement along tracks or rails. With their ability to reduce friction, handle high loads, and offer versatility in design, yoke type track rollers are a valuable component in a variety of applications. Whether used in conveyors, cranes, hoists, or AGVs, these rollers contribute to the efficiency and reliability of material handling equipment, making them an indispensable part of the industry.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano