Methods of Controlling Cross Roller Ring Bearing Noise

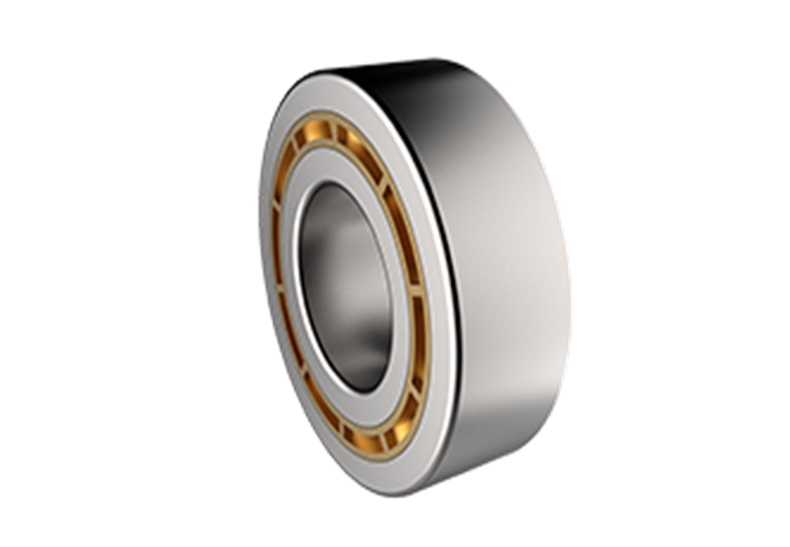

In modern industrial precision machinery, cross roller ring bearings are highly favored for their high rigidity, high precision, and high load capacity. However, after long periods of operation, bearings may produce abnormal noises, which can not only affect the efficiency of machinery but also signal more severe faults. There are various reasons for bearing noise, and resolving these issues requires an in-depth understanding of the bearing's working principles and maintenance knowledge. This article will delve into noise control methods for cross roller ring bearings to help maintenance personnel diagnose and address these common problems promptly.

Accurate Installation to Ensure Proper Bearing Positioning

First, the installation accuracy of cross roller ring bearings is a critical factor affecting their operational state. If the bearing is improperly installed or if there is an angle deviation during installation, it can lead to uneven contact between the inner and outer rings and the shaft or bearing housing, thus causing abnormal noise. Therefore, ensuring the correct installation of the bearing is the first step in noise control. This includes using appropriate tools and techniques, avoiding forceful installation, and ensuring the precise fit between the bearing, shaft, and bearing housing.

Optimize Lubrication to Reduce Friction

Lubrication is another key factor in the normal operation of bearings. Appropriate lubricants can reduce internal bearing friction, thereby lowering temperature and noise. Choosing the correct lubricant viscosity, ensuring adequate supply of the lubricant, and regularly checking the viscosity and cleanliness of the lubricant, replacing it when necessary, are effective measures to reduce noise.

Regular Cleaning to Prevent Contaminants Affecting Performance

Dust and foreign objects inside the cross roller ring bearings are common causes of noise. Hence, regularly cleaning the bearings to remove internal contaminants is essential for noise prevention. This not only includes cleaning the bearings themselves but also maintaining a clean working environment to prevent contaminant intrusion.

Adjust Preload to Control Bearing Clearance

The bearing clearance, or the internal gap of the bearing, has a direct impact on noise generation. Excessive or insufficient clearance can lead to noise. By adjusting the preload of the bearing, the clearance can be controlled, thus reducing noise. This requires determining the appropriate clearance range based on the specific application and working conditions of the cross roller ring bearings.

Using Dampening Devices to Absorb Vibration Energy

In certain applications, using dampening devices such as damping spring pads can absorb the vibration energy during bearing operation, thereby reducing noise. These devices need to be correctly installed to ensure they work effectively without negatively impacting the normal operation of the Bearings.

Select Appropriate Bearings to Meet Operational Requirements

Selecting the appropriate type and specification of bearings based on the operating conditions and performance requirements of the equipment is also crucial for noise control. For demanding applications, higher-grade cross roller ring bearing can be chosen, as these typically have better materials and manufacturing processes, capable of withstanding higher loads and speeds, thus reducing noise.

Enhance Routine Maintenance to Extend Bearing Life

Regular inspection and maintenance are key to ensuring long-term smooth operation of bearings. This includes checking the rotational flexibility of the bearings, their lubrication condition, and cleanliness. By promptly identifying and resolving potential issues, noise can be prevented, and the lifespan of the bearings can be extended.

Noise control for cross roller ring bearings is a comprehensive issue involving various aspects, requiring consideration of installation, lubrication, cleaning, preload adjustment, dampening devices, bearing selection, and routine maintenance. By taking appropriate measures, we can effectively control the noise of cross roller ring bearings, ensure the smooth operation of machinery, and create a quieter working environment for staff.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano