The Working Principle of Slewing Ring

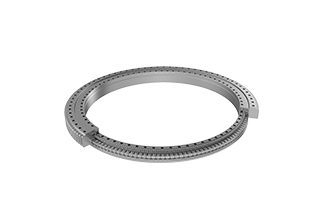

The working principle of the slewing ring bearing is very simple: the way of moving the object is from sliding to rolling, reducing frictional resistance.

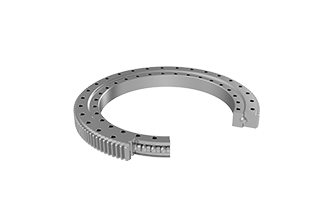

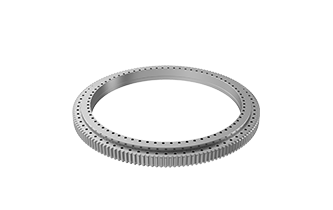

Specifically, the slewing ring mainly relies on lubrication and friction to achieve the effect of operation. Internally, the slew ring bearing relies on the mutual friction between the ball and the steel ring to achieve the purpose of operation. Externally, it also relies on the friction between the slew bearing (the own or later added gear) and other components (drive gears, etc.) to start the operation and rub against each other, thereby driving the object to operate. Since it is mostly used to carry heavier large objects, its centripetal force is very high, which is also determined by its working principle, so it also needs a steel material that can ensure quality in terms of materials.

Of course, it is far from enough only with friction. Although it relies on friction to operate, lubrication is also essential. Just like the chain of a bicycle, if it is used for a long time and the friction is too large, it will also affect the use of parts. Therefore, after using this kind of slew bearings for a period of time, it is necessary to maintain it in time. Brush some lubricating oil or grease (on the external friction surface) and regularly lubricate the inside of the raceway to ensure that it can work well in a more suitable environment. Slewing bearing manufacturers recommend regular maintenance to prolong the lifespan and efficiency of the bearings.

The Daily Maintenance of Slewing Ring

1. After 100 working hours of operation, the slewing bearing should be maintained once and the pre-tightening torque of the secondary bolts should be checked.

2. If more than 10% of the bolts are loosen, check again after 200 working hours.

3. In the future, check every 500 working hours; in severe working conditions, the inspection interval should be shortened.

4. After the equipment has been working for 2000 hours, if a bolt is found to be loose to less than 80% of the specified torque, the bolt and the two adjacent bolts should be replaced with new ones.

5. If 20% of the bolts are found to be loose to less than 80% of the specified torque, the bolts should be replaced with new ones.

6. After the equipment has been working for 14,000 hours, the bolts must be replaced with new ones.

7. For equipment with high rotation speed or continuous rotation or frequent work, add oil every 100 working hours.

8. In the case of bad working conditions, it is necessary to shorten the time interval for filling lubricating grease.

FAQs of Slewing Ring

1. What is a slewing bearing?

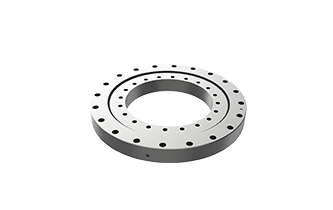

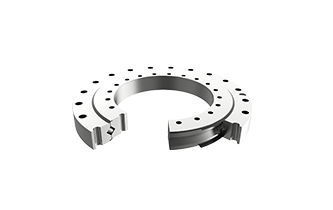

Slewing bearings, also known as turntable bearings, are large bearings that facilitate the smooth rotation of heavy loads. Their unique design allows for axial, radial, and moment loads to be supported simultaneously, making them ideal for applications requiring precise and controlled rotational movement.

2. What is a turntable bearing?

The slewing ring turntable bearing is a kind of large bearing with special structure that can accept large axial load, radial load and overturning moment and other comprehensive loads at the same time, and integrates various functions such as support, rotation, transmission and fixation.

3. How to properly store the slewing bearing?

Before installation, it is important to handle and store the slewing bearing properly to prevent damage. When moving the bearing, use appropriate lifting equipment to avoid dropping or mishandling. Store the bearing in a clean, dry environment to protect it from dust, moisture, and other contaminants that could affect performance.

4. How to treat the oil leakage of the slewing ring bearing?

If it is caused by sealing, the old slewing bearing seal should be removed, the sealing slot should be cleaned with diesel or gasoline, and the new seal should be completely inserted into the sealing slot. It should be noted that after the sealing strip becomes a circular shape, there is a joint that needs to be glued together with double-sided adhesive.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano