What are the Types of Cam Followers?

When it comes to achieving precise and controlled motion in mechanical systems, cam followers play a crucial role. These ingenious components follow the contours of a cam or track surface, converting rotary motion into linear motion with minimal friction. In this article, we'll delve into the world of cam followers, exploring their different types, functionalities, and applications. Join us as we unravel the diversity of cam followers and their contribution to the realm of mechanical motion.

Stud-Type Cam Followers

One of the most common types of cam followers is the stud-type cam follower. As the name suggests, these followers feature a stud or shaft that acts as the mounting point and provides support. The stud is equipped with a roller or needle bearing that follows the cam or track surface. Stud-type cam followers come in various designs and configurations, allowing for different load capacities, sizes, and sealing options. They find applications in a wide range of industries, including automotive, packaging, and material handling, where they ensure smooth and precise motion in demanding environments.

Yoke-Type Cam Followers

Yoke-type cam followers, also known as eccentric cam followers, offer a different design approach. Instead of a stud, they feature a yoke or roller body that serves as the mounting point. The yoke-type cam followers incorporate a roller or needle bearing and often have a threaded shaft or bolt for easy installation. These followers excel in applications that require high radial load-carrying capacity and shock resistance. They are commonly used in construction equipment, agricultural machinery, and cam-operated mechanisms where durability and ruggedness are essential.

Additional Types of Cam Followers

Crowned Cam Followers

Crowned cam followers have a crowned outer surface that compensates for minor misalignments and uneven loads. This design feature helps distribute the load evenly on the roller or needle bearings, reducing stress and extending the service life of the follower. Crowned cam followers are ideal for applications with misalignment challenges, such as conveyors and guide systems.

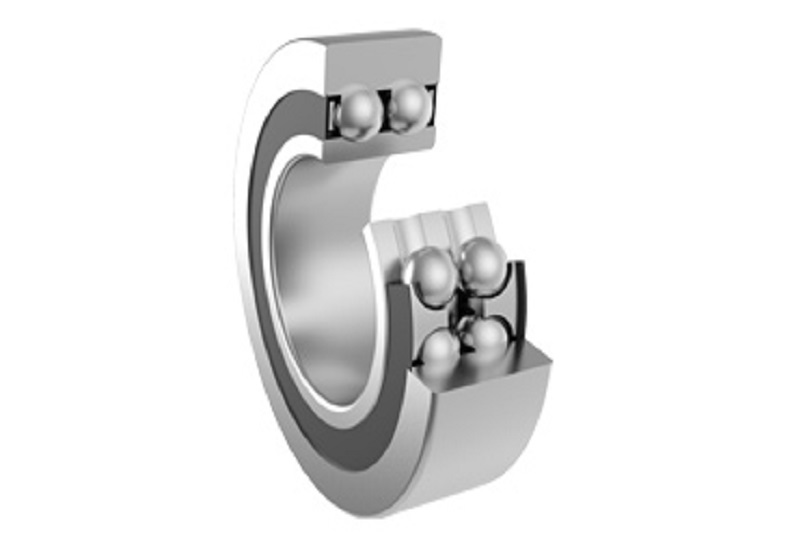

Caged Cam Followers

Caged cam followers incorporate a cage or separator to separate the rolling elements, ensuring smoother operation and reduced friction. The cage keeps the rollers or needles evenly spaced, preventing them from contacting each other during high-speed motion. This design improves performance, reduces wear, and enhances overall efficiency. Caged cam followers are commonly used in printing machinery, packaging equipment, and machine tools.

Heavy-Duty Cam Followers

As the name suggests, heavy-duty cam followers are designed to handle extremely high loads and withstand harsh operating conditions. They feature robust construction, larger rolling elements, and enhanced sealing capabilities. Heavy-duty cam followers are used in heavy machinery, construction equipment, and mining applications, where durability and load capacity are paramount.

Cam followers are versatile components that facilitate smooth and precise motion in a wide range of mechanical systems. From stud-type followers to yoke-type followers, each type offers unique characteristics and benefits for specific applications. Whether it's providing support in automotive systems, ensuring stability in packaging machinery, or handling heavy loads in construction equipment, cam followers play a crucial role in achieving efficient and reliable motion. By understanding the different types of cam followers and their functionalities, engineers and designers can select the most suitable follower for their specific application needs, ultimately contributing to the seamless operation of mechanical motion systems.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano