Plummer Bearings in Automation Systems

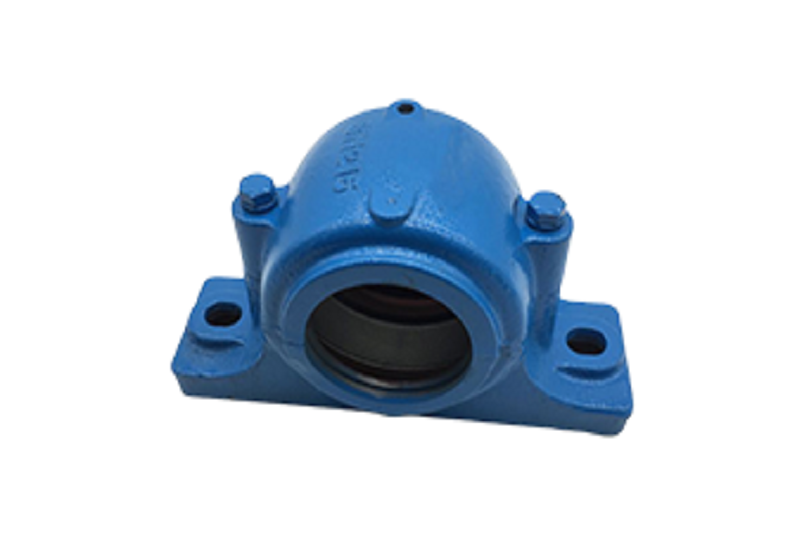

In the fast-paced world of automation systems, precision and reliability are key factors for success. One crucial component that plays a major role in ensuring the smooth operation of automation systems is the plummer bearing. Plummer bearings, also known as pillow block bearings, are designed to provide support and smooth rotation for shafts in various industrial applications. Let's take a closer look at the importance of plummer bearings in automation systems.

What are Plummer Bearings?

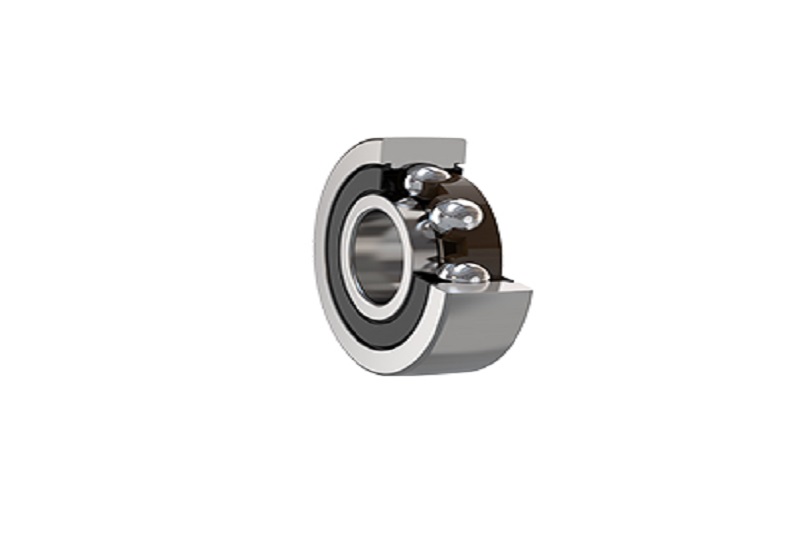

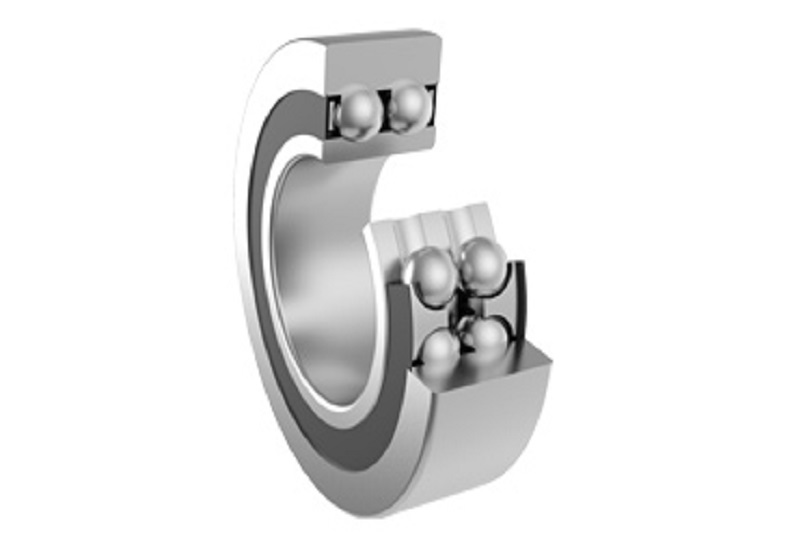

Plummer bearings are a type of rolling-element bearing that consists of a housing or pedestal (plummer block) and a bearing insert. The housing is typically made of cast iron or steel and is designed to provide support and secure the bearing insert in place. The bearing insert, on the other hand, is the component that actually supports the rotating shaft. Plummer bearings come in various designs and sizes to accommodate different shaft diameters and loads.

Importance of Plummer Bearings in Automation Systems

In automation systems, plummer bearings play a critical role in ensuring the smooth and reliable operation of machinery. These bearings provide support for shafts, help reduce friction and wear, and improve overall efficiency. Without plummer bearings, shafts in automation systems would not be able to rotate smoothly, leading to increased friction, wear, and potential system failures. By using plummer bearings, manufacturers can ensure that their automation systems operate smoothly and efficiently, resulting in improved productivity and reduced downtime.

Benefits of Using Plummer Bearings in Automation Systems

There are several benefits to using plummer bearings in automation systems. One of the main advantages is their ability to support heavy loads and provide reliable operation under high speeds. Plummer bearings are also easy to install and maintain, making them a cost-effective solution for manufacturers. Additionally, plummer bearings are designed to withstand harsh operating conditions, such as high temperatures and corrosive environments, making them suitable for a wide range of industrial applications.

Applications of Plummer Bearings in Automation Systems

Plummer bearings are used in a variety of automation systems, including conveyors, food processing equipment, packaging machinery, and robotics. These bearings are commonly found in applications where precision and reliability are essential, such as in manufacturing plants, automotive assembly lines, and warehouses. Plummer bearings are also used in industries that require continuous and high-speed operation, such as mining, construction, and energy production. Overall, plummer bearings are a versatile and reliable solution for supporting shafts in automation systems.

In conclusion, plummer bearings are an essential component in automation systems, providing support and smooth rotation for shafts in various industrial applications. These bearings play a critical role in ensuring the reliability and efficiency of machinery, reducing friction, wear, and potential system failures. By using plummer bearings, manufacturers can improve productivity, reduce downtime, and enhance the overall performance of their automation systems. With their numerous benefits and applications, plummer bearings are a reliable solution for supporting shafts in automation systems.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano