Agv Automatic Guided Vehicle with Crossed Roller Bearings for Unmanned Handling

AGV, commonly known as AGV car, refers to a transportation vehicle equipped with automatic guidance devices such as electromagnetic or optical, capable of traveling along predetermined paths, with safety protection and various transfer functions, and is a driverless handling vehicle in industrial applications. It is powered by rechargeable batteries. Its travel route and behavior can generally be controlled through a computer or by setting up its travel route using electromagnetic rails, which are pasted on the floor. The unmanned handling vehicle then relies on the information provided by the electromagnetic rails to move and act.

AGV, also known as unmanned handling vehicle, automatic navigation vehicle, or laser navigation vehicle, is characterized by having no human driver. The AGV is equipped with an automatic guidance system, which ensures that the system can automatically travel along the predetermined route without human navigation, transporting goods or materials from the starting point to the destination automatically. Another characteristic of the AGV is its flexibility, high automation and high intelligence. The travel path of AGV can be flexibly changed according to the requirements of storage locations, production processes, and other factors, and the cost of changing the travel route is much lower than that of traditional conveyor belts and rigid conveying lines. The AGV is generally equipped with loading and unloading mechanisms, which can be automatically interfaced with other logistics equipment to realize the full automation of loading and unloading, and handling of goods and materials. Moreover, AGV also has the feature of clean production. AGV relies on its own rechargeable batteries to provide power, and produces no noise or pollution during operation, making it suitable for many places that require clean working environments. The storage industry is the earliest place where AGV bearing products were used. In 1954, the world's first AGV was put into operation at a company's warehouse in the United States to achieve automatic handling of goods entering and exiting the warehouse.

AGV's small cars with bearings play a big role on the production line in the manufacturing industry, efficiently, accurately and flexibly completing the task of transporting materials

They can also form flexible logistics transfer systems consisting of multiple AGV small cars with bearings, and the transport route can be adjusted in a timely manner with changes in the production process, allowing a production line to manufacture more than a dozen products, greatly increasing production flexibility and corporate competitiveness. In 1974, a Swedish car assembly plant used an automatic car assembly line based on AGVS as the carrying tool in order to improve the flexibility of the transportation system. The assembly line was composed of multiple AGVS that can load car bodies. After adopting this assembly line, the assembly time was reduced by 20%, assembly failures were decreased by 39%, investment return time was reduced by 57%, and labor was decreased by 5%. Currently, AGV has been widely used in the manufacturing and assembly lines of major car manufacturers in the world, such as General Motors, Toyota, Chrysler, and Volkswagen.

In recent years, as a basic handling tool of CIMS, the application of AGV has penetrated into many industries such as mechanical processing, home appliance production, microelectronics manufacturing, and cigarette rolling. Production and processing have become the most widely used fields for AGV application.

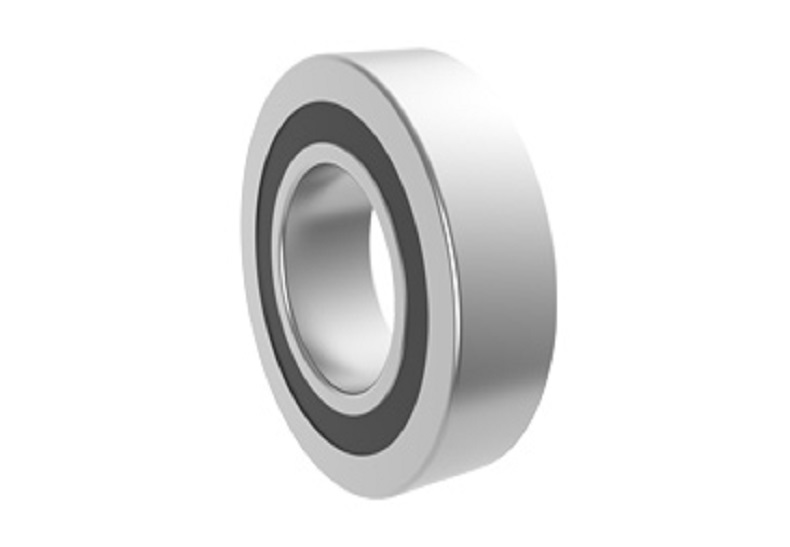

The AGV's small cars with bearings have characteristics such as light weight, fast response speed, and long operating time

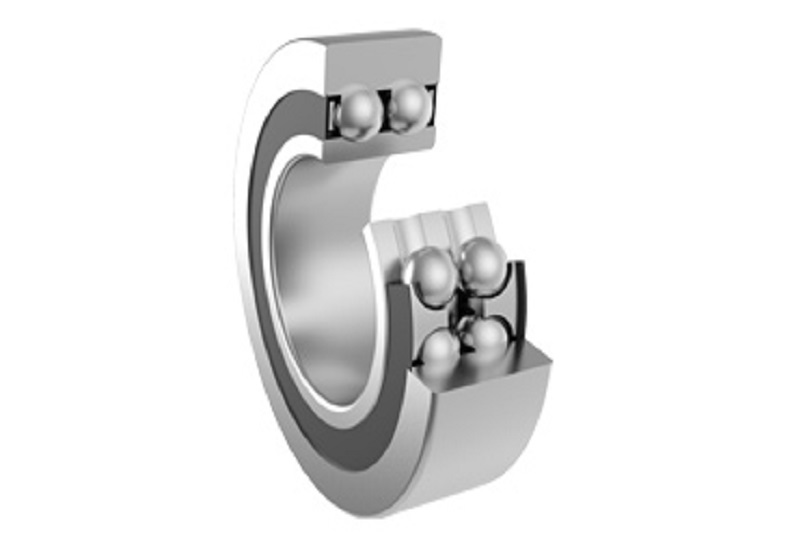

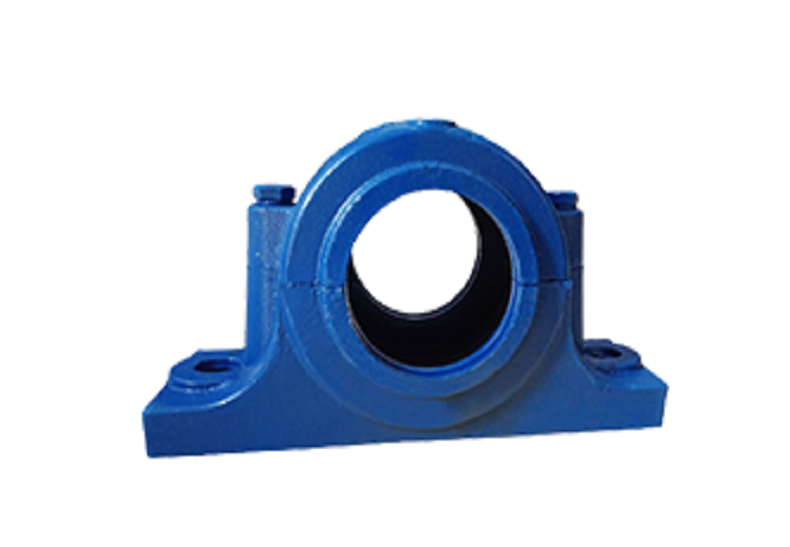

Warehouse AGV's lift and turn mechanism supporting bearings require characteristics such as small friction torque, large load-bearing capacity, long life, and wear resistance, while the industrial traction AGV's steering mechanism supporting bearings requires characteristics such as flexible rotation, large load bearing capacity, and long life.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano