Vibration of the Bearing and Inspection of Its Temperature

1. Inspection of bearing vibration

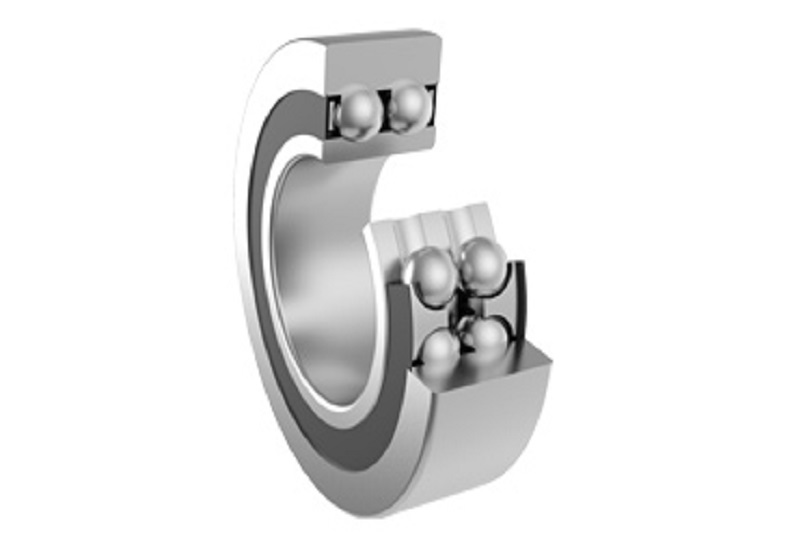

Bearing vibration is very sensitive to bearing damage, such as spalling, indentation, rust, cracks, wear, etc. will be reflected in the bearing vibration measurement, so, through a special bearing vibration measuring instrument (frequency analyzer, etc.) can measure the vibration. The size of the abnormality cannot be inferred by frequency analysis. The measured values differ depending on the operating conditions of the bearing or the installation position of the sensor. Therefore, it is necessary to analyze and compare the measured values of each machine in advance to determine the judgment standard.

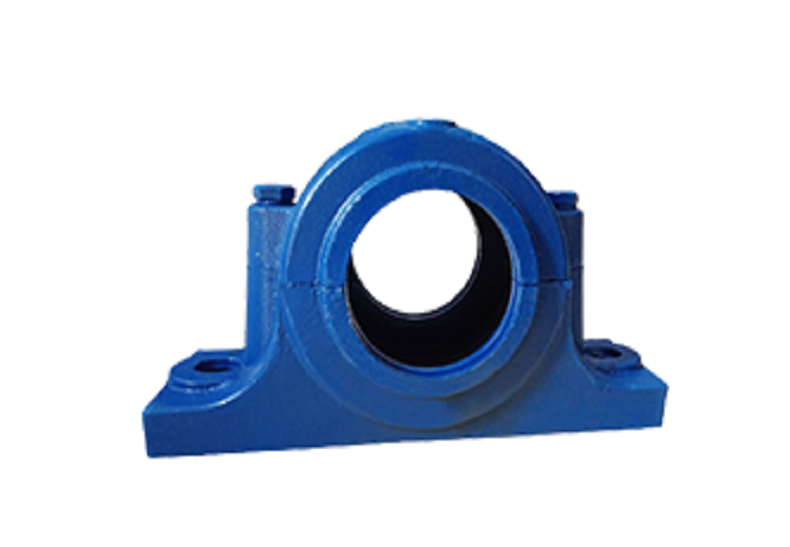

2. Check the bearing temperature

The temperature of the bearing can generally be inferred from the temperature outside the bearing chamber. It is more appropriate to use the oil hole to directly measure the temperature of the outer ring of the bearing. Usually, the temperature of the bearing starts to rise slowly with the operation of the bearing, and reaches a steady state after 1-2 hours. The normal temperature of the bearing varies with the heat capacity, heat dissipation, speed and load of the machine. If the lubrication and installation are not suitable, the bearing temperature will rise sharply and abnormally high temperature will occur. At this time, the operation must be stopped and necessary preventive measures should be taken.

The use of thermal sensors can monitor the working temperature of the bearing at any time, and realize automatic alarm or stop when the temperature exceeds the specified value to prevent the occurrence of burning shaft accidents. A high temperature often indicates that the bearing is in an abnormal condition. High temperatures are also detrimental to bearing lubricants. Sometimes bearing overheating can be attributed to the lubricant of the bearing. If the bearing is continuously rotated for a long time at a temperature exceeding 125°C, the bearing life will be reduced. Causes of high temperature bearings include: insufficient or excessive lubrication, lubricants. Contains impurities, excessive load, bearing damage, insufficient clearance, and high friction caused by oil seals, etc. Therefore, it is necessary to continuously monitor the temperature of bearing products, whether it is to measure the bearing itself or other important parts. If the operating conditions remain unchanged, any temperature change may indicate a malfunction.

Regular measurement of bearing temperature can be done with the aid of a thermometer, such as a digital thermometer, which can accurately measure bearing temperature and display it in °C or Fahrenheit units. The important bearing means that when it is damaged, it will cause the downtime of the equipment, so it is best to install a temperature detector on this type of bearing. Under normal circumstances, bearing products will have a natural temperature rise that lasts for a day or two immediately after lubrication or relubrication.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano