Navigating Precision: Support Rollers in CNC Machining Applications

CNC machining has revolutionized the manufacturing industry, providing engineers and designers with immense control and precision in the creation of complex parts. One crucial component in this process is the support roller. In this blog, we will explore the importance of support rollers in CNC machining applications and how they contribute to achieving accurate and efficient results.

Understanding Support Rollers

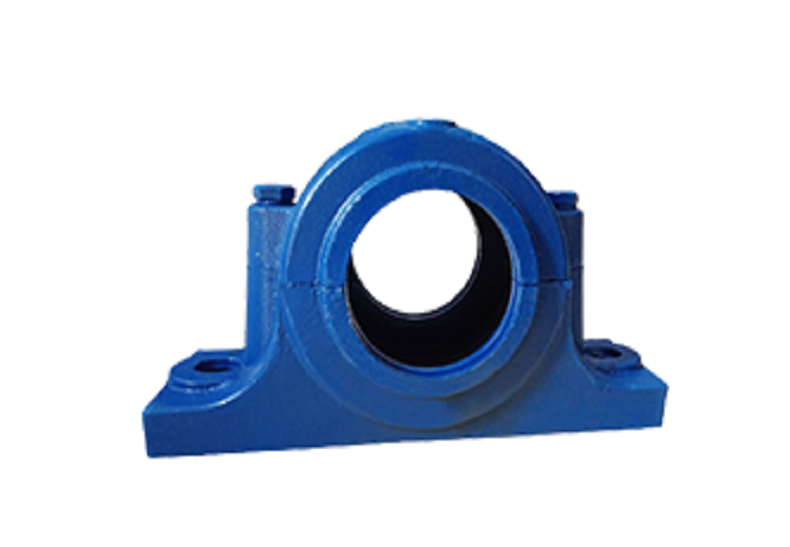

Support rollers, also known as guide rollers or track rollers, play a vital role in various CNC machining applications. These rollers are designed to support and guide the movement of different components within the machine, ensuring smooth and precise operation. They are commonly used in applications such as conveyor systems, printing presses, and machinery used in material handling.

Advantages of Support Rollers

Support rollers offer several advantages that make them indispensable in CNC machining applications. Firstly, they help minimize friction and wear by reducing the contact area between the moving parts, ensuring longevity and minimizing maintenance requirements. Secondly, support rollers enhance the stability of the machine, reducing vibrations and improving overall performance. Additionally, these rollers assist in load distribution, particularly in heavy-duty applications, preventing unnecessary stress on specific components.

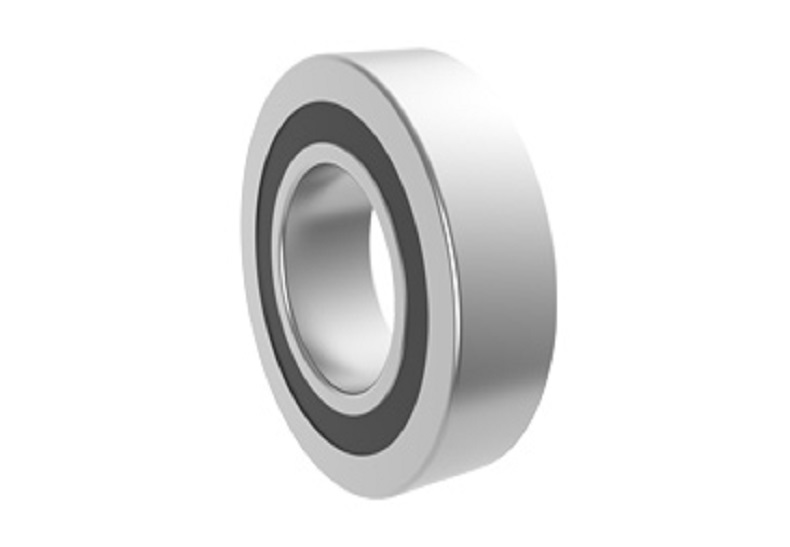

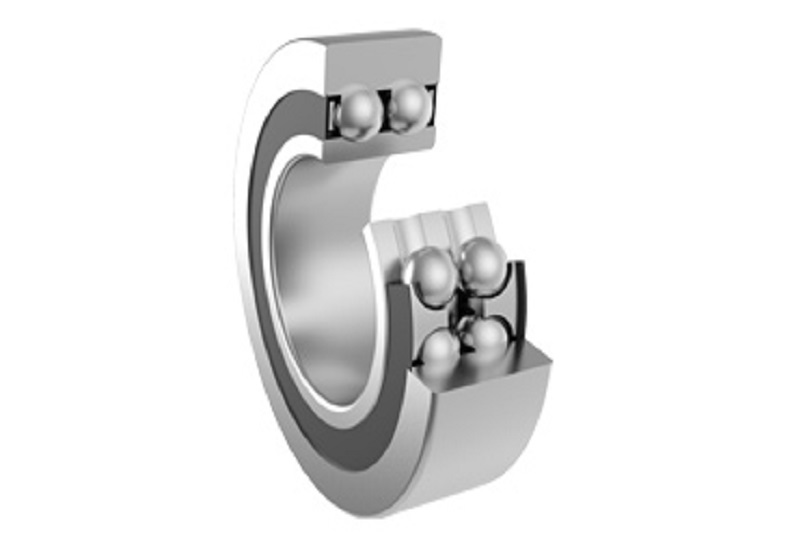

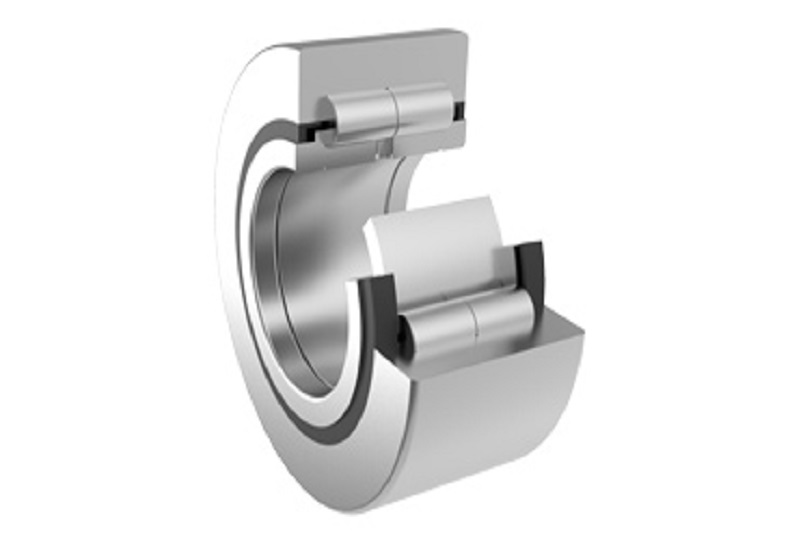

Types of Support Rollers

Support rollers come in various shapes and sizes, depending on the specific application requirements. Some common types include cylindrical rollers, needle rollers, and ball-bearing rollers. Cylindrical rollers offer a large contact area, making them suitable for heavy load applications. Needle rollers, on the other hand, are ideal for applications with limited space due to their compact design. Ball-bearing rollers provide excellent radial and axial load capabilities, making them versatile for a wide range of machining tasks.

Choosing the Right Support Rollers

Selecting the appropriate support rollers for CNC machining applications requires careful consideration of various factors, such as load capacity, speed, temperature, and the type of material being processed. It is essential to understand the specific requirements of the application to ensure optimal performance and longevity of the support rollers. Consulting with experienced professionals or working closely with reputable bearing manufacturers like THB BEARINGS can help in selecting the right support rollers that align with your machining needs.

In conclusion, support rollers are an essential component in CNC machining applications, enabling precise movement, improved stability, and enhanced load distribution. Understanding the various types available and their advantages can help in choosing the right support rollers for specific applications. When it comes to quality bearings and support rollers, THB BEARINGS is a trusted brand known for its exceptional precision and durability. So, make sure to consider THB BEARINGS and their wide range of support rollers for your CNC machining requirements.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano