Understanding the Essential Role of Slewing Bearings in Modern Machinery

In the world of machinery and industrial applications, the efficiency and reliability of rotating systems play acritical role. One key component that enables smooth and controlled rotational motion is the slewing bearingOften overlooked, these ingenious devices are essential in various sectors, including construction, renewable energy, robotics, and material handling. In this article, we will delve into the world of slewing bearings, exploring their design, functionality, applications, and the benefits they offer in the modern industrial landscape.

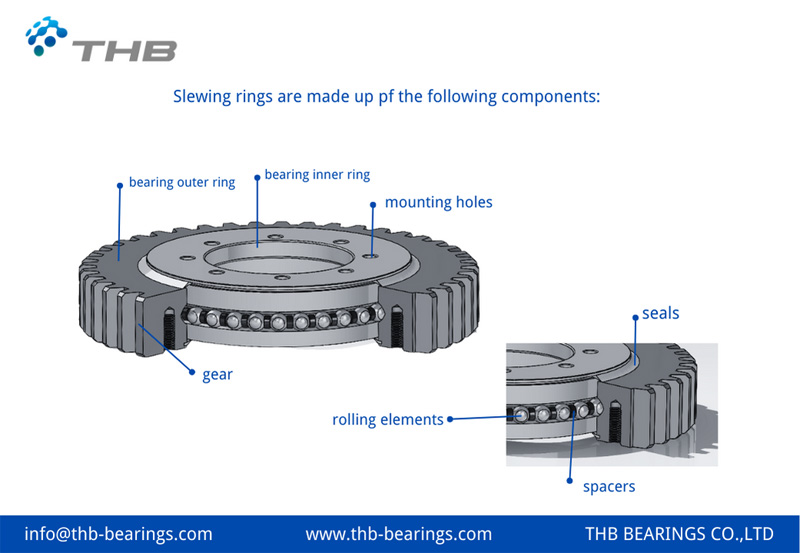

What Is A Slewing Bearing?

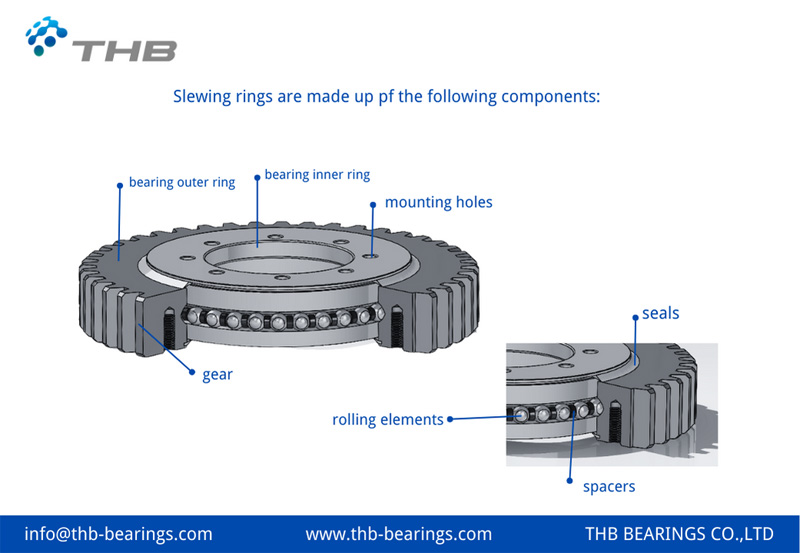

Slewing bearings, also known as turntable bearings, are large bearings that facilitate the smooth rotation of heavy loads. Their unique design allows for axial, radial, and moment loads to be supported simultaneously, making them ideal for applications requiring precise and controlled rotational movement.

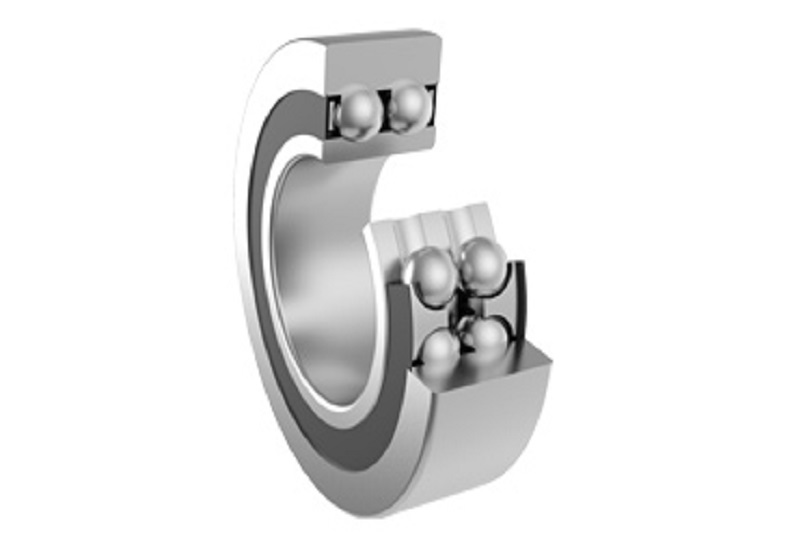

Slewing bearings consist of an inner and outer ring, rolling elements (balls or rollers), a cage,and, in some cases, gear teeth.

How Does a Slewing Ring Work?

The inner and outer toothed rings of the slewing bearing are connected through rolling elements (balls or rollers) to reduce friction, allowing the inner and outer rings to rotate relative to each other.

During rotation, if axial and radial forces are applied, the rolling element will roll on the raceway, thereby dispersing and bearing the force, reducing overall wear and tear.

If a tipping moment is applied, the structural design of the slewing bearing can effectively prevent changes in the relative position of the inner and outer rings, thus it can withstand the tipping moment.

The gear on the toothed ring of the slewing bearing can be connected to the drive. Through the drive's operation, the inner and outer toothed rings can rotate relative to each other, completing the equipment's task.

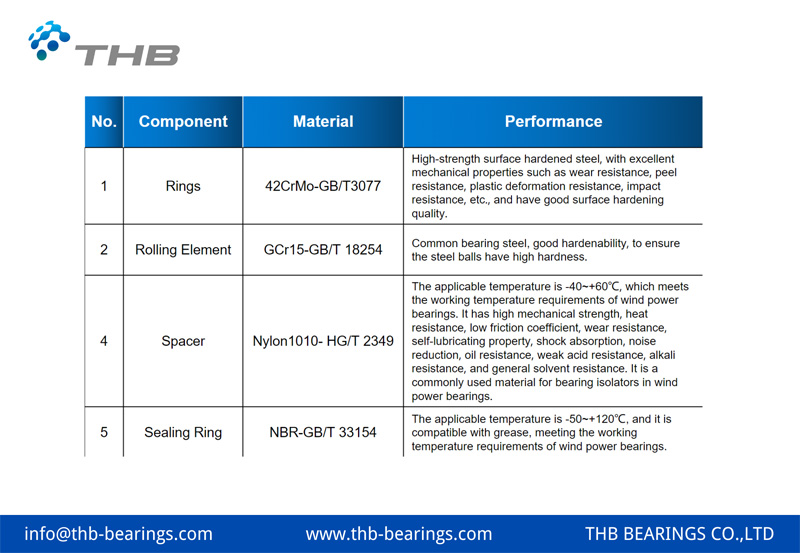

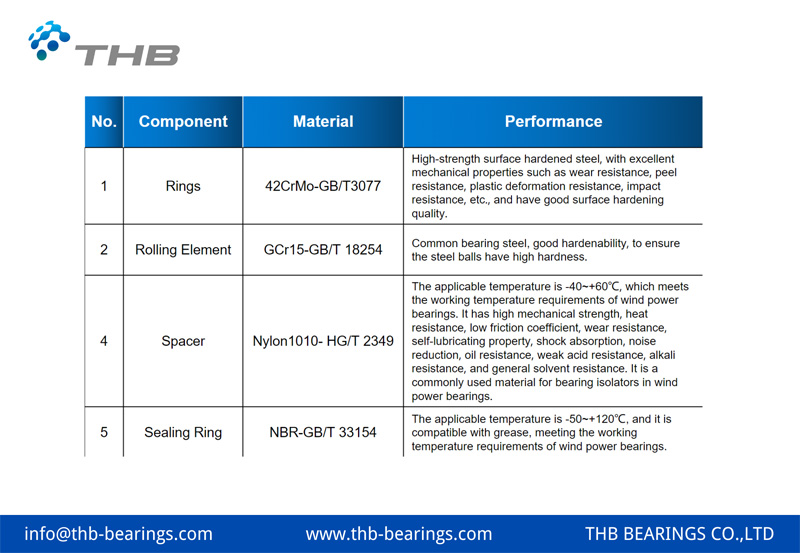

What Materials Are Used In Slewing Bearings?

Professional and accurate design and the correct and reasonable choice of bearing manufacturing materials are important to ensure that THB slewing rings have high performance and high reliability.

1. Rolling elements

The rolling of the slewing ring is usually made of bearing steel grade GCrl5 or GCrl5SiMn;

2. Inner and outer ring

The rings are made of surface hardened steel 42CrMo or 50Mn;

If the host or the working environment has special requirements, it can also be made of 440C, 420C and other stainless steel or other grades of 45 steel.

3. Spacer

THB slewing rings have different types of cages, such as isolation block type, integral cage and segmented cage, which are suitable for Different working conditions need.

The integral cage or segmented cage is made of brass, carbon steel, cast aluminum and nylon.spacer cages are made of polyamide resin, nylon, cast aluminum or aluminum bronze.

4. Seals

THB slewing ring seals are made of oil-resistant nitrile rubber.

For applications requiring higher minimum and maximum temperatures, we can use fluoroelastomer seals or other special sealing materials.

Considering Factors for Slew Ring Bearing Design

In designing and selecting slewing ring bearings, we need to consider the following key factors in detail:

1. Accuracy

The accuracy of the bearing includes dimensional, rotational, and shape accuracy. Different applications require different levels of accuracy. For example, high-precision bearings are needed for satellite antennas, precision turntables, and robot arms. Improvements in bearing accuracy can be achieved by optimizing the bearing structure and manufacturing process and by increasing the precision of component manufacturing.

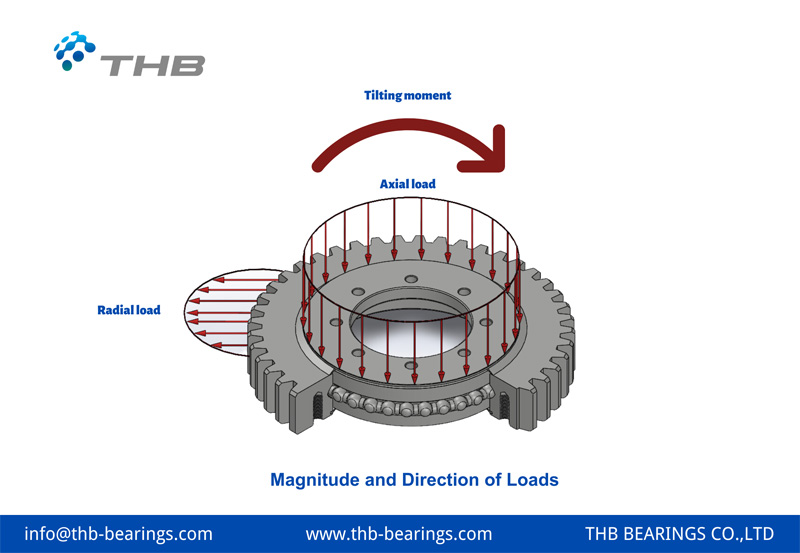

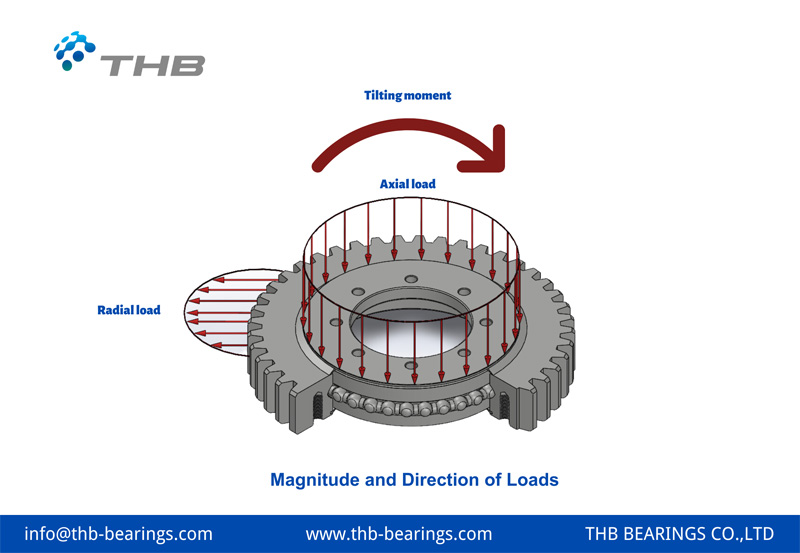

2. Magnitude and Direction of Loads

The bearings need to withstand radial, axial loads and overturning moments. During the design process, it's important to fully assess the load conditions in all directions and consider both dynamic and static loads and the detailed load spectrum. For different load conditions, choose the appropriate type of slewing ring bearing, such as single-row four-point contact ball, double-row four-point contact ball, cross roller, or three-row roller types.

3. Permissible Operating Temperature

For most conventional applications, the suggested operating temperature range for most slewing ring bearings is from -30℃ to +100℃. Within this range, the bearing materials and standard lubricants can maintain good performance. In high-temperature environments like in metallurgy and mining industries, slewing ring bearings may need to operate at temperatures from 100℃ to 200℃. For these applications, we need to select materials with better high-temperature stability or high-temperature alloy steels, use suitable lubricants for high-temperature environments along with appropriate sealants, and use isolators or retainers made of materials that can withstand these temperatures to ensure the normal operation of the bearings. For low-temperature environments, like in polar equipment and cold storage equipment, where slewing ring bearings may need to operate at temperatures from -30℃ to -60℃ or even lower, we need to select bearing materials with good low-temperature performance and apply special low-temperature lubricants along with appropriate sealants and insulators or retainers to ensure the normal operation of the bearings.

4. Vibration

In designing slewing ring bearings, it is crucial to analyze and evaluate external and internal sources of vibration. The impact of vibrations on bearing performance can be reduced by selecting bearing materials with good impact resistance, optimizing the raceway curve design, and choosing an appropriate shock and vibration-resistant structure.

5. Operating Speed

Different types of slewing ring bearings are suitable for different ranges of operating speeds. For instance, four-point contact ball slewing ring bearings are suitable for higher-speed rotations, while roller slewing ring bearings are suitable for medium and low-speed rotations. The design needs to take into consideration the actual speed requirements of the application.

6. Sealing

A sealing system can prevent dust, moisture, and other contaminants from entering the bearing. Depending on the operating conditions and the environment, select sealing materials that can withstand various temperatures and seal types that can better adapt to environmental sealing requirements to ensure the seal's effectiveness and longevity.

7. Raceway Design

The raceway design greatly affects the bearing's load-bearing capacity, service life, and coefficient of friction. Improvements in bearing performance can be achieved by optimizing the shape of the raceway (such as the conformity coefficient of the raceway, optimizing the raceway modifications), increasing the number of rolling elements, or applying special coatings or other surface treatments.

8. Lubrication

There are two methods of lubrication, oil lubrication, and grease lubrication. The purpose of lubrication is to decrease friction, reduce wear, prevent rust, and provide cooling. Based on the actual application, choose the appropriate lubrication system (like centralized lubrication, automatic point lubrication, or regular manual lubrication) and types of lubricants (like mineral oil, synthetic oil, extreme pressure grease).

9. Gear Arrangements

Slewing ring bearings can be integrated with gears, making them more suitable for various applications. There are three types of gear arrangements: internal, external, and gearless. Internal gears are suitable for applications with limited external dimensions, while external gears are suitable for applications with larger loads. Choose the appropriate gear arrangement based on the actual application requirements. The precision of the slewing ring bearing gear can be set to different levels according to different usage scenarios. Higher gear precision can be achieved through gear grinding to meet higher transmission precision requirements. According to requirements, the surfaces and roots of the gears can also be hardened to enhance overall gear strength and wear resistance.

By considering all these factors comprehensively and combining bearing application knowledge, design, and choose the appropriate slewing ring bearing to meet the needs of specific application scenarios. Meanwhile, during the use of slewing ring bearings, regular maintenance, and inspection of the bearings are also necessary to ensure their long-term stable operation.

What are the advantages of slewing bearings?

Slewing ring bearings, exhibit unique characteristics that set them apart from other types of bearings.

Here are some distinguishing features:

1. Load Capacity

Slewing ring bearings are designed to handle complex load spectra including axial, radial, and moment loads. This is a unique feature compared to other bearings which typically only accommodate axial or radial loads.

2. Rotation

Unlike most bearings that facilitate high-speed rotations, slewing bearings are designed for low-speed, high-torque applications. They are capable of accommodating slow and controlled pivotal or rotational movements.

3. Design

Slewing bearings typically feature a large diameter and thin cross-section. The design also includes an inner ring, outer ring, and rolling elements (either balls or rollers) which may be separated by spacers. Another vital feature is gear teeth incorporated on either the inner or outer ring, allowing it to interface with external gears.

4. Application

Slewing bearings are commonly used in heavy machinery or equipment that require 360-degree rotation, such as cranes, wind turbines, excavators, and radar systems. This contrasts with many other bearings which are used in applications like electric motors, automobiles, and household appliances.

5. Mounting

Slewing ring bearings are usually bolted down with mounting holes on both the inner and outer rings, whereas most other bearings are press-fit into housings.

6. Integration

Slewing bearings can often be integral to the structure of the machine, serving as both a bearing and a structural component. This is not typically the case with other bearings.

In summary, slewing ring bearings are specialized bearings designed to support heavy loads, slow rotation, and oscillation movements, which makes them different from other standard bearings. Their unique design, incorporating gear teeth and mounting holes, allows for efficient power transmission and secure attachment, respectively. Furthermore, their ability to serve as both a bearing and a structural component demonstrates their critical role in the functionality of heavy machinery and systems requiring rotational movement. Hence, slewing ring bearings are not only integral moving parts but also critical to the structural integrity of the machinery they are incorporated in.

Slewing Bearing Application Industries

Slewing bearings find diverse applications across multiple industries due to their ability to support heavy loads, facilitate smooth rotation, and provide precise positioning. Here are some notable applications of slewing bearings:

1. Construction and Heavy Equipment

Slewing bearings are extensively used in construction machinery and heavy equipment, such as cranes, excavators, tower cranes, concrete pumps, and mobile platforms. They enable the rotation of the superstructure and the lifting and movement of heavy loads with stability and precision. Slewing bearings in construction machinery are designed to withstand high loads and harsh operating conditions.

2. Renewable Energy

Slewing bearings play a crucial role in wind turbines. They allow the nacelle (the housing that contains the generator and other components) to rotate and adjust its position to maximize energy capture from the wind. Slewing bearings in wind turbines must withstand dynamic loads, high wind forces, and continuous rotation for efficient power generation.

3. Material Handling and Conveyor Systems

Slewing bearings are employed in various material handling equipment, including stackers, reclaimers, ship loaders, and conveyor systems. They facilitate the controlled movement of bulk materials, enabling efficient loading, unloading, and stacking processes in industries such as mining, ports, and logistics.

4. Robotics and Automation

Slewing bearings are integral components in robotic systems, industrial manipulators, and automation equipment. They enable precise and controlled movement in multiple axes, allowing robots to perform complex tasks with accuracy and repeatability. Slewing bearings provide stability and support for robotic arms, enabling them to handle various payloads and operate in diverse environments.

5. Industrial Machinery

Slewing bearings are utilized in a wide range of industrial machinery, including turntables, indexing tables, industrial cranes, and rotating platforms. They allow smooth and controlled rotation, enabling precise positioning and movement in manufacturing processes, assembly lines, and other industrial applications.

6. Aerospace and Defense

Slewing bearings are employed in aerospace and defense applications, such as radar systems, satellite antennas, missile launchers, and turret systems. They provide reliable and precise movement, allowing for accurate tracking, positioning, and pointing in critical defense operations.

7. Medical Equipment

Slewing bearings are used in medical equipment, such as CT scanners, MRI machines, and robotic surgical systems. They enable smooth rotation and precise movement, facilitating accurate imaging and surgical procedures.

8. Entertainment Industry

Slewing bearings find application in amusement park rides, observation wheels, and rotating stages. They enable safe and smooth rotation, delivering thrilling experiences and enhancing the visual presentation in entertainment venues.

These are just a few examples of the broad range of applications for slewing bearings. Their versatility, load-carrying capacity, and ability to provide controlled rotational motion make them indispensable components in numerous industries that rely on heavy machinery, automation, and precise movement.

In summary:

Slewing bearings are essential components in modern machinery, enabling smooth, controlled rotation in various applications.

Their ability to handle heavy loads, facilitate precise positioning, and provide reliable performance makes them indispensable in industries such as construction, wind energy, mining, aerospace, and manufacturing.

As technology continues to advance, the demand for slewing bearings with enhanced capabilities and durability is expected to grow, driving further innovation in this critical field of engineering.

THB Bearings is a professional supplier of slewing bearings with a mission to provide specialized solutions for diverse applications.

Leveraging our expertise and experience, we cater to the specific needs of our customers, offering high-quality, durable, and efficient slewing bearings.

We're proud to present our in-house brand, RORKS Bearings, designed and manufactured with a commitment to reliability and performance. Trust THB Bearings for your slewing bearing solutions, and experience the difference quality makes.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano