Under Pressure: Support Rollers in Heavy-Duty Hydraulic Presses

When it comes to heavy-duty hydraulic presses, support rollers play a critical role in ensuring the smooth operation and longevity of these powerful machines. Whether you are forging metal parts, shaping automotive components, or producing construction materials, support rollers are essential for maintaining stability, distributing weight, and reducing friction as these presses exert immense pressure to shape and form materials. In this blog, we will explore the importance of support rollers in heavy-duty hydraulic presses and how they contribute to efficient and reliable operations.

The Significance of Support Rollers

Support rollers provide a crucial function by evenly distributing the weight of the pressing plates in hydraulic presses. As these machines exert immense pressure, it is essential to have a system in place that can bear this load without compromising the structural integrity of the press. Without support rollers, the excessive weight could result in premature wear and tear or even catastrophic failure of the press. By evenly distributing the load, support rollers ensure that the hydraulic press stays aligned and stable during operation.

Reducing Friction for Enhanced Performance

In addition to bearing weight, support rollers also help in minimizing friction within the hydraulic press. Friction can be a major challenge in heavy-duty machinery, leading to energy loss, increased wear on components, and decreased efficiency. With the inclusion of support rollers, the weight distribution is optimized, reducing friction between moving parts and consequently enhancing the overall performance of the hydraulic press. The reduced friction enables smoother movement, faster cycle times, and ultimately higher productivity.

Durability and Longevity

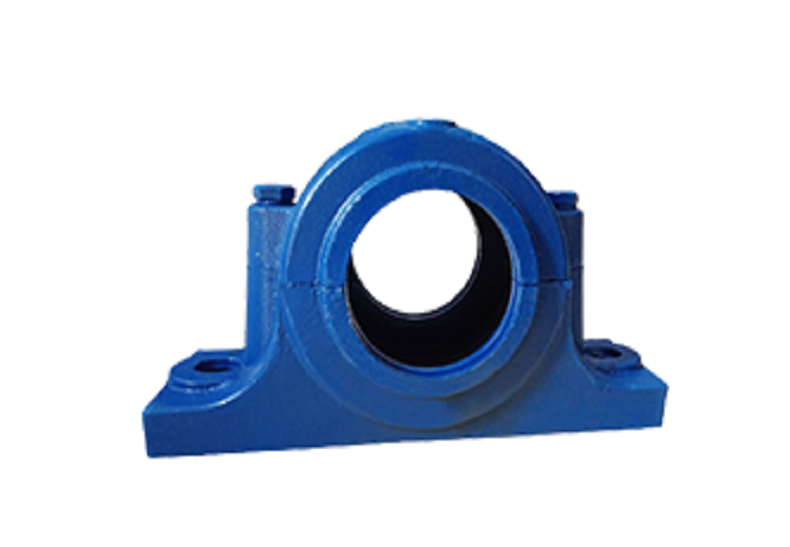

Heavy-duty hydraulic presses are subjected to demanding working conditions, making durability of crucial importance. Support rollers are engineered to withstand the immense pressures and strains these machines encounter daily. High-quality support rollers, such as those manufactured by THB BEARINGS, are designed with durable materials and precision engineering to ensure they can endure heavy loads without succumbing to premature wear and tear. By investing in reliable support rollers, businesses can prolong the lifespan of their hydraulic presses and minimize the need for frequent maintenance or replacement.

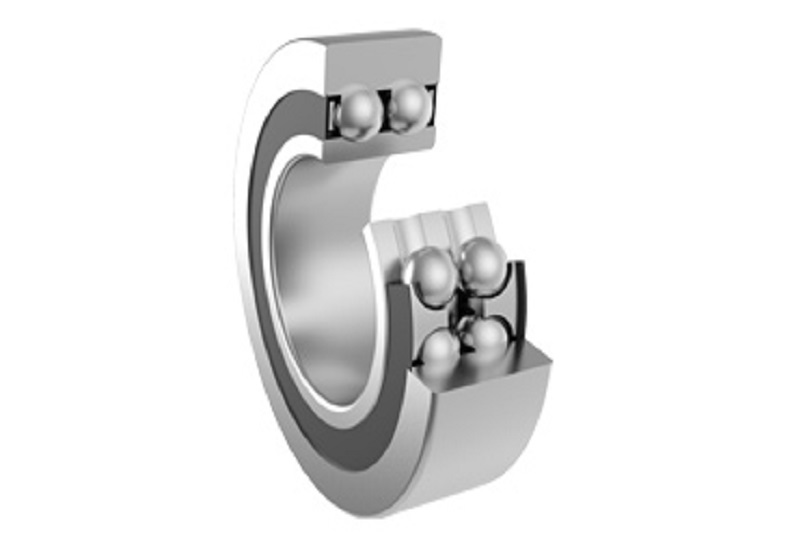

Advanced Designs for Optimal Support

As technology advances, so do the designs and capabilities of support rollers for hydraulic presses. Innovative features, such as anti-seizure properties, self-aligning capabilities, and advanced sealing, contribute to an even higher level of support and performance. THB BEARINGS, a trusted brand in the industry, offers a range of support roller designs that incorporate these advancements to provide optimal support and reliability even in the most challenging operational scenarios. With THB BEARINGS' superior support rollers, businesses can rest assured that their heavy-duty hydraulic presses will operate efficiently and effectively.

Support rollers are a fundamental element in heavy-duty hydraulic presses, ensuring stable operations, reducing friction, and promoting overall durability. Their ability to evenly distribute weight and minimize wear and tear makes them indispensable components in these powerful machines. As businesses rely on hydraulic presses to perform demanding operations, investing in high-quality support rollers, such as those from THB BEARINGS, is crucial for maintaining productivity, reliability, and longevity. By understanding the significance of support rollers and their role under pressure, businesses can optimize the performance of their heavy-duty hydraulic presses and drive success in their operations.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano