Railway to Reliability: V Groove Bearings in Material Handling Systems

In the realm of material handling systems, reliability is the linchpin that ensures seamless operations. A key player in achieving this reliability is the often-underestimated V Groove Bearing Track. In this exploration, we'll uncover the critical role of V Groove Bearings in material handling systems and how they act as the railway to unwavering reliability.

Unveiling the V Groove Advantage in Material Handling

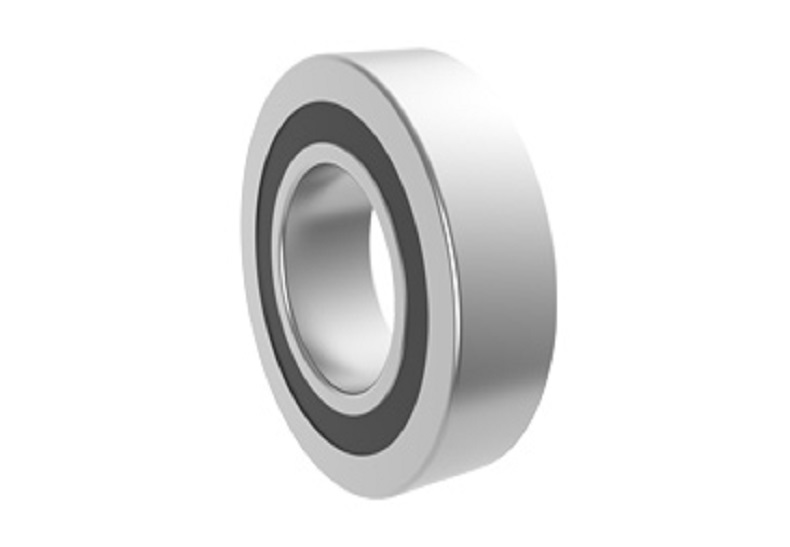

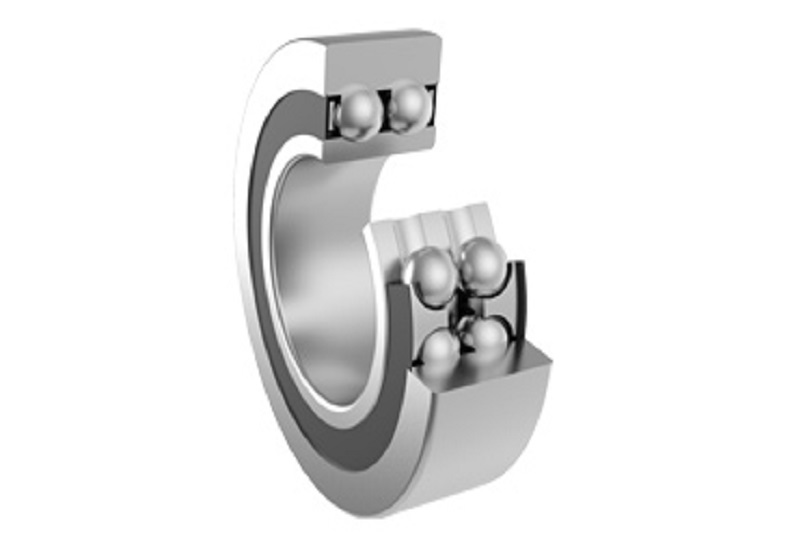

Material handling systems form the backbone of numerous industries, from warehouses to manufacturing plants. V Groove Bearings play a pivotal role in these systems, providing the necessary guidance for linear motion. The V Groove design ensures a secure fit for the bearings, preventing slippage and facilitating the smooth movement of heavy loads. This design feature is fundamental in enhancing the reliability of material handling systems, ensuring that goods are transported with precision and efficiency.

Optimizing Linear Motion for Efficiency

Efficiency is the heartbeat of any material handling operation. V Groove Bearings, with their ability to optimize linear motion, contribute significantly to the efficiency of material handling systems. Whether it's a conveyor belt carrying products through a distribution center or an automated picking system in a manufacturing facility, the reliability of V Groove Bearings ensures that the linear motion remains consistent, reducing downtime and enhancing overall system productivity.

Applications Across Material Handling Industries

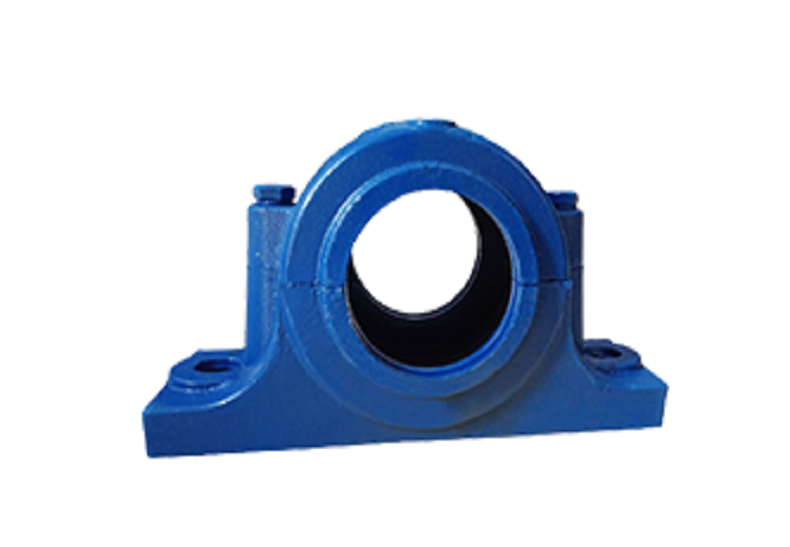

The versatility of V Groove Bearing makes them indispensable in a variety of material handling applications. From roller conveyors and sliding doors to automated packaging lines, these bearings find their place in diverse settings. Their ability to withstand heavy loads and harsh industrial environments positions them as a reliable choice for engineers and designers tasked with creating robust material handling systems.

Enhanced Durability for Cost-Efficient Operations

Material handling systems operate in demanding conditions, often subjected to continuous cycles of loading and unloading. V Groove Bearings, designed for durability, contribute to the cost-efficiency of material handling operations. Their robust construction minimizes the need for frequent replacements, reducing maintenance costs and ensuring that material handling systems operate reliably over the long term.

As material handling technology evolves, so do the demands placed on components like V Groove Bearings. Innovations in materials and design are pushing the boundaries of what is possible. The railway to reliability in material handling systems continues to be paved by advancements in V Groove Bearing Track technology, ensuring that these systems remain at the forefront of efficiency and performance.

The role of V Groove Bearings in material handling systems is pivotal. Acting as the railway to reliability, these bearings optimize linear motion, enhance efficiency, and contribute to the overall success of material handling operations. As industries continue to rely on the seamless movement of goods, the importance of V Groove Bearings in ensuring this reliability cannot be overstated.

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano