What Are the Benefits of Using Crossed Roller Bearings on Industrial Robots?

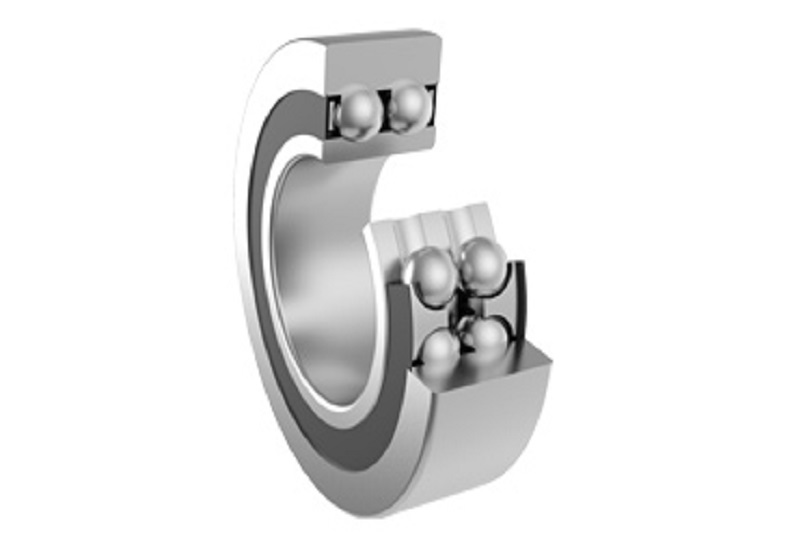

Cross roller bearings are a type of bearing commonly used on industrial robots, particularly in the joints. They are renowned for their simplicity of operation, high precision, and unique design structure. Today, we will detail the benefits of using cross roller bearings in industrial robots.

Cross roller bearings can withstand large axial and radial loads

Cross roller ring bearings can withstand large loads and moments from all directions, including radial, axial, and various other forces. This makes them ideally suited for the external forces that joints of industrial robots face during operation.

Cross roller bearings are easy to install

Cross roller bearings have a two-part construction with inner and outer rings. Rollers and retainers can be conveniently installed together, making the operation installation process for cross roller bearings very simple.

Cross roller bearings save installation space

With high rigidity, small size, and wide usage, cross roller bearings can effectively reduce the installation space required. They are commonly utilized in precision critical areas like joints and rotating parts of industrial robots.

Cross roller bearings have high rotational precision

The internal structure of cross roller bearings uses rollers arranged at 90° angles to one another, which efficiently prevents the increase of rotational torque. Additionally, even when subjected to pressure, the bearing can automatically adjust gaps and prevent roller locking, resulting in a high level of rotational precision.

Cross roller bearings belong to a type of bearing commonly used in industrial production, and have significant importance in the emerging industrial robot industry. In recent years, cross roller bearings have replaced thrust roller bearings and radial roller bearings that demand both axial and radial loads simultaneously. One set of cross roller ring bearings can replace the need for both kinds of bearings. This matching design philosophy has been broadly utilized. Though cross roller bearings have excellent quality and performance, they are precision components and must be used with discretion. Regardless of the quality of the bearing, improper use can result in accidents. Severe pressure can cause marks, dents, cracks, or even fractures in cross roller bearings, so proper usage is essential.

The above details the benefits of using cross roller bearings on industrial robots. Overall, cross roller bearings are an appropriate bearing for use on industrial robots, given their flexibility, load-bearing capacity, and ease of installation. If you have any additional questions regarding cross roller bearings, please don't hesitate to consult with us at TuoHong!

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano