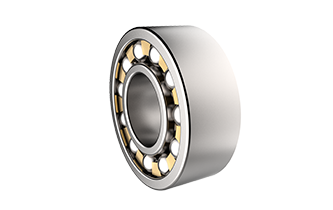

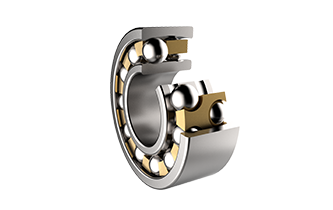

Self-aligning ball bearings have two rows of balls and two continuous tracks of deep groove ball type in the inner ring. The outer ring has a spherical track with the center of curvature coinciding with the center of curvature of the bearing. This gives the inner ring, the balls, and the shaft of the cage a deflection area. Self aligning linear ball bearings are mainly used to carry radial loads and light axial loads, but cannot carry pure axial loads. THB-Bearings is a professional self aligning ball bearing manufacturer offering you two types of self aligning linear ball bearings as follows. The followings are self-aligning bearing types. Click and check more information about self aligning linear ball bearings.

-

Products

- Track Roller

- Deep Groove Ball Bearing

- Self-aligning Ball Bearing

- Angular Contact Ball Bearing

- Thrust Ball Bearing

- Needle Roller Bearing

- Cylindrical Roller Bearing

- Spherical Roller Bearing

- Tapered Roller Bearing

- Thrust Roller Bearing

- Crossed Roller Bearing

- Slewing Ring

- Pillow Block Bearing

- Plain Bearing

- Track Roller

- Industries

- Technical Service

-

Knowledge Center

- Company

- News

- Contact Us

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano