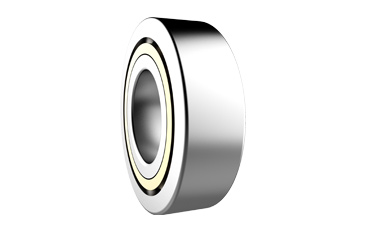

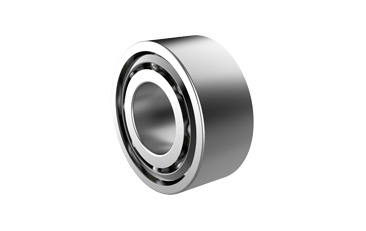

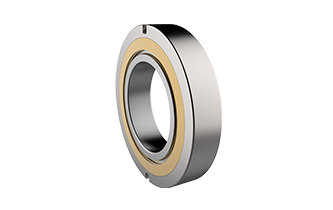

Angular contact ball bearings can be used to bear combined load, that is, to bear radial load and axial load at the same time, its bearing capacity increases proportionately with the increase of the contact angle.

-

Products

- Track Roller

- Deep Groove Ball Bearing

- Self-aligning Ball Bearing

- Angular Contact Ball Bearing

- Thrust Ball Bearing

- Needle Roller Bearing

- Cylindrical Roller Bearing

- Spherical Roller Bearing

- Tapered Roller Bearing

- Thrust Roller Bearing

- Crossed Roller Bearing

- Slewing Ring

- Pillow Block Bearing

- Plain Bearing

- Track Roller

- Industries

- Technical Service

-

Knowledge Center

- Company

- News

- Contact Us

English

English  français

français  Deutsch

Deutsch  italiano

italiano

English

English  français

français  Deutsch

Deutsch  italiano

italiano